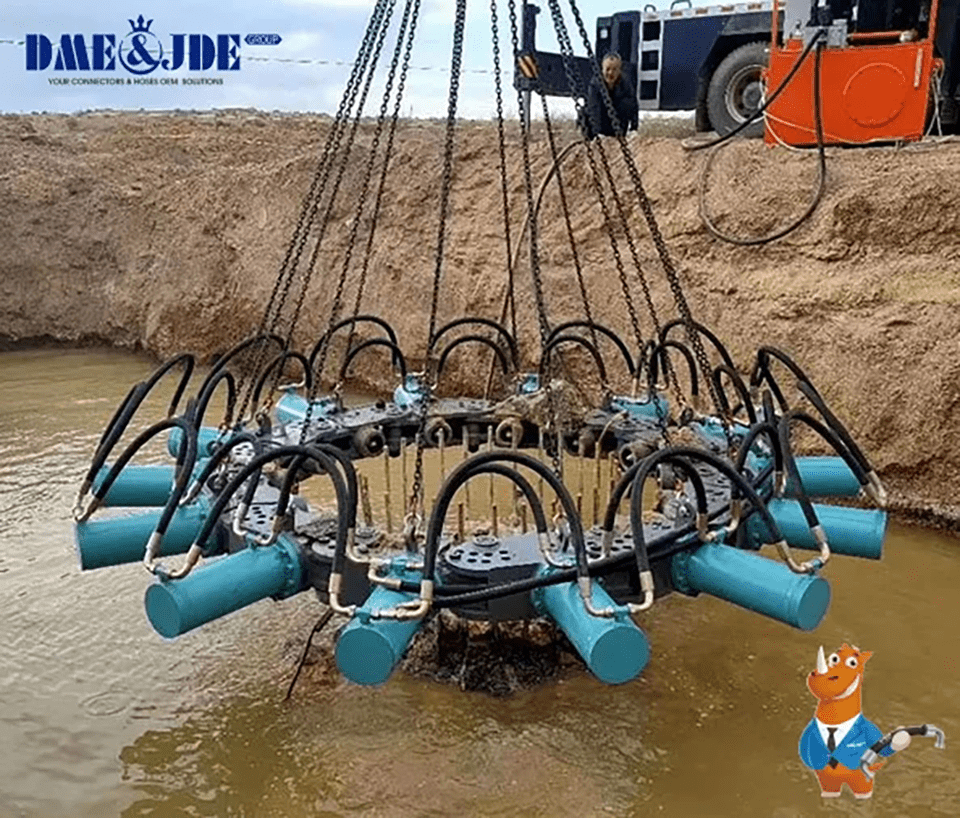

Super Shield-flex series products, on the basis of the original "Shield" series, once again improve various performances, far exceeding EN853/EN856 and SAEJ517. It is widely used in construction machinery, highway machinery, marine machinery, mining machinery, building equipment, petroleum equipment, etc. for its superior performance.

-

Improve impulse performance, improve quality without increasing price

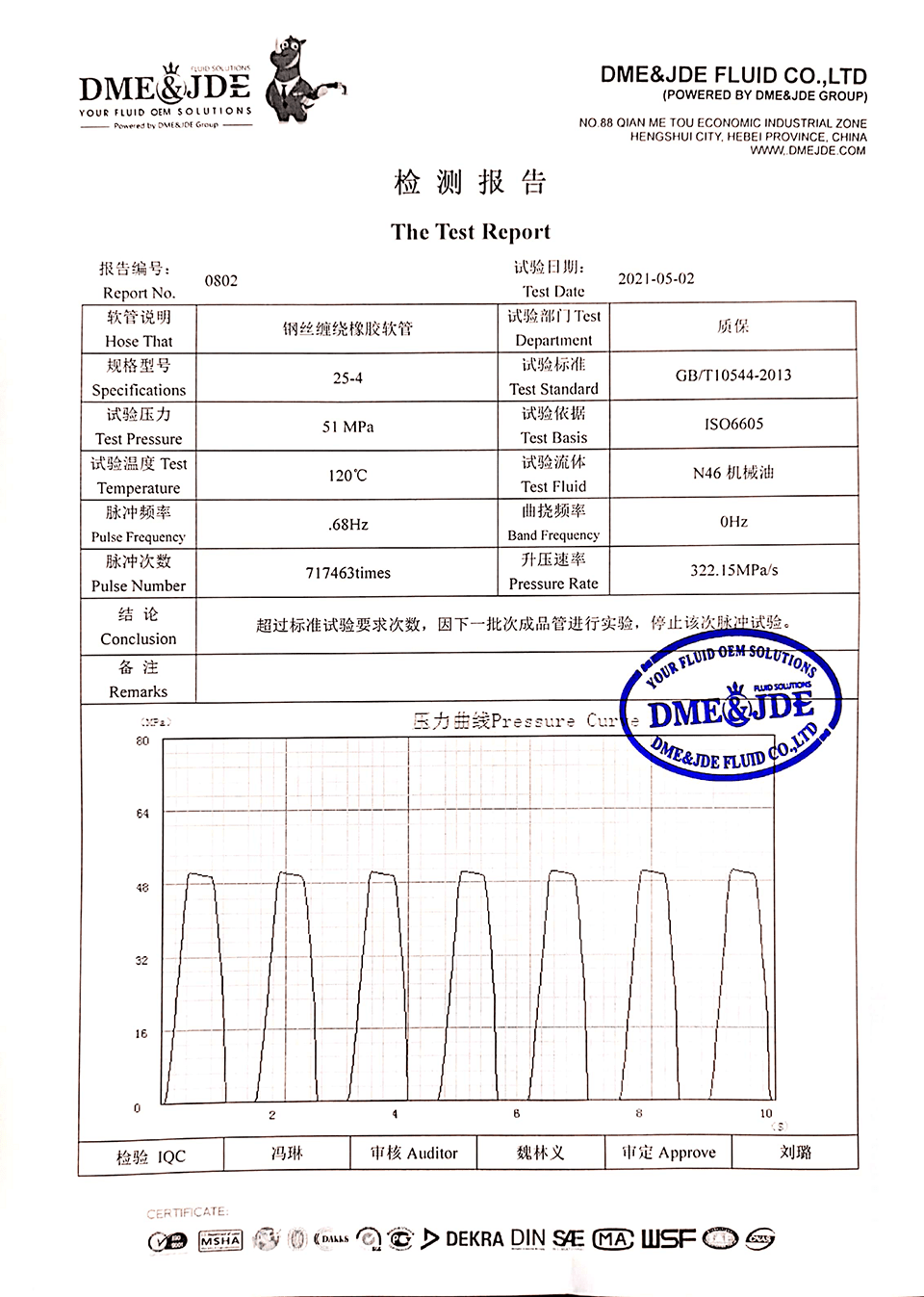

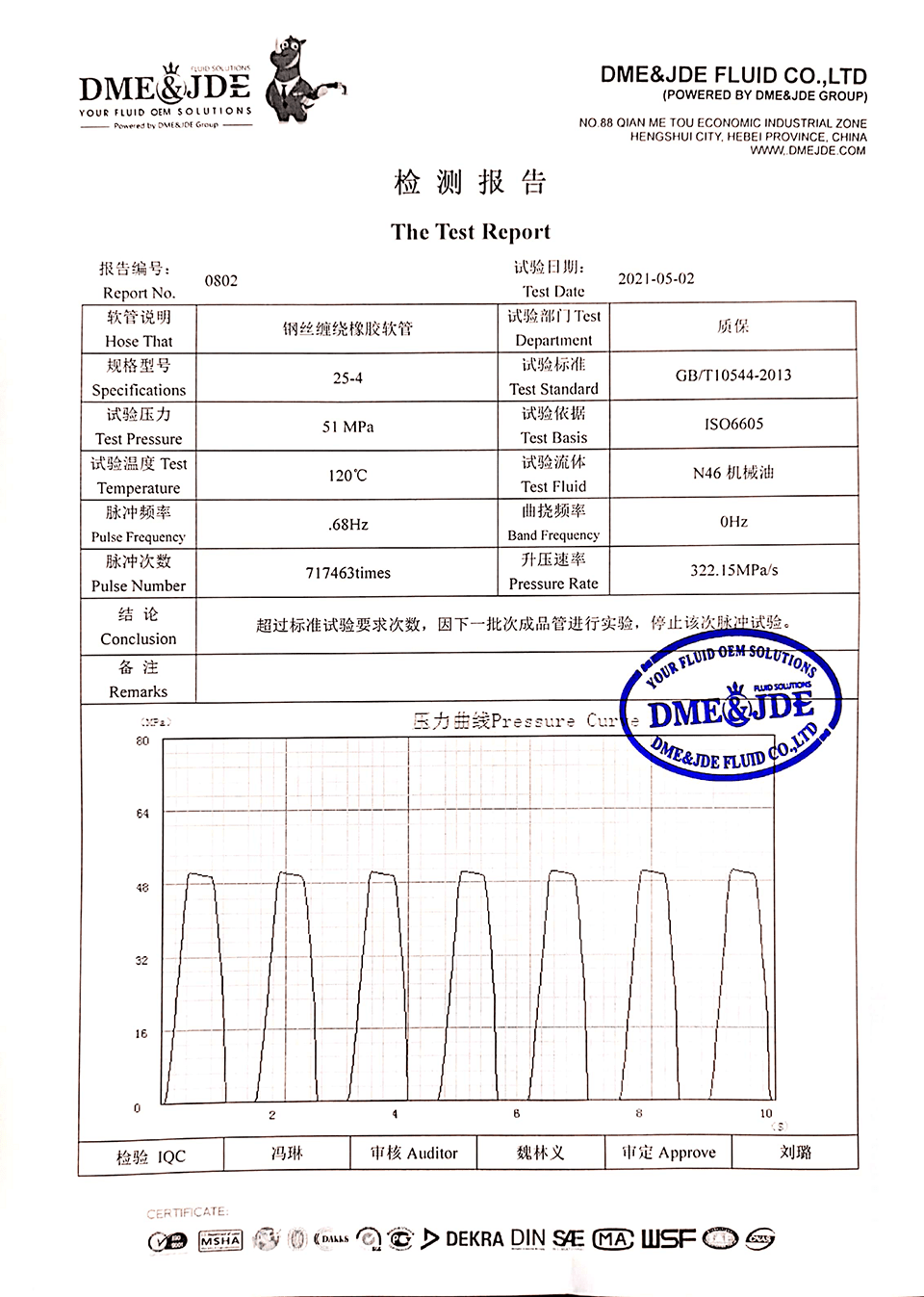

Our four-layer and six-layer spiral reinforced hose can increase the impulse test to 700,000 times, and the customized spiral hose products even exceed 1 million times, exceeding the standard by 75%, which makes the "Super Shield-flex" series products more stable in performance and bear more missions during use.

"Super Shield-flex"series part of hose impulse test report (as shown below)

-

Improve the pressure and temperature resistance, and improve the performance without increasing price.

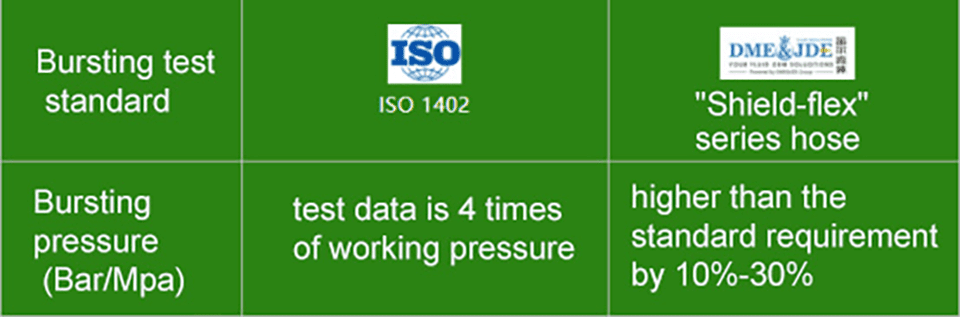

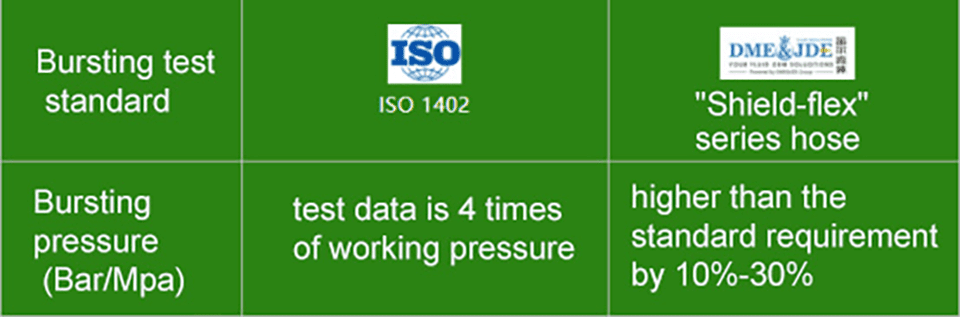

"Super Shield-flex" series products are made of imported synthetic rubber materials (mainstream advanced full-automatic closed internal mixing equipment, full-automatic computer-controlled batching closed production line, and comprehensive control of defects in the production process of hydraulic hose compound). Rubber layer is extruded integrally and continuously, with no joints and uniform thickness. The bursting pressure test of products is higher than the standard requirement by 10%–30%. The use temperature is from -40 °C to +100 °C (intermittent 120 °C).

Bursting pressure test (as shown below):

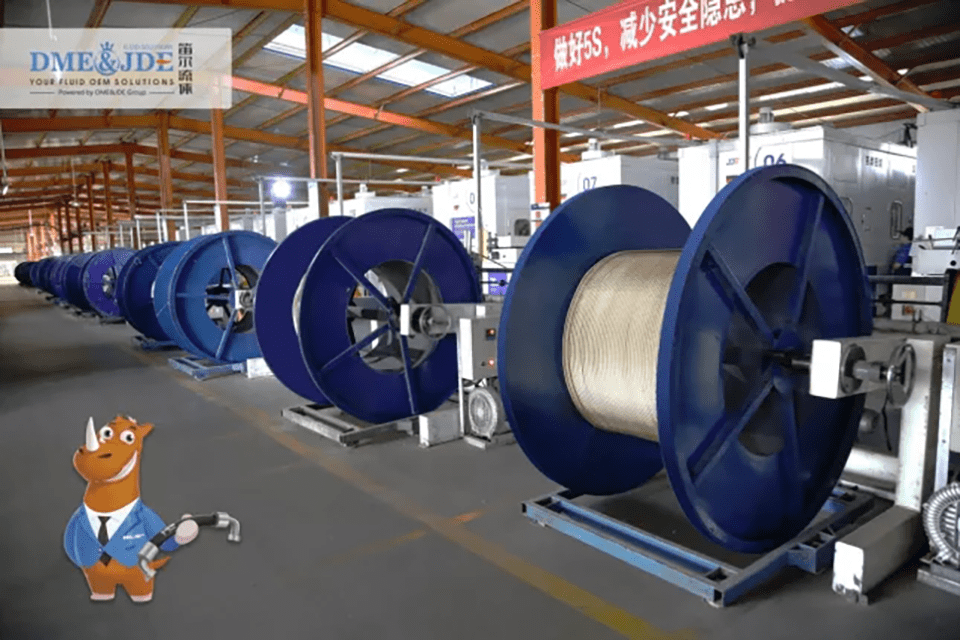

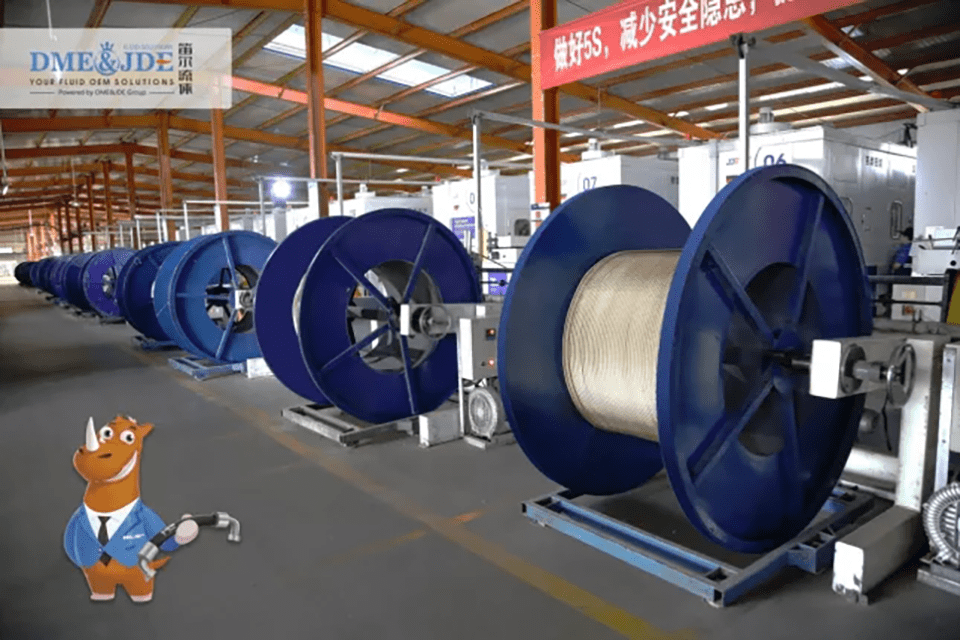

Mainstream advanced full-automatic closed internal mixing equipment (as shown below):

-

Use German equipment to produce 3x3 square openings, speed up without increasing price.

14 sets of automatic high-speed German braiding machines (pictured) were introduced, with automatic fault stop system to eliminate the quality problems caused by manual errors. The machine runs at high speed and stably, and the quality of finished products is controlled stably.

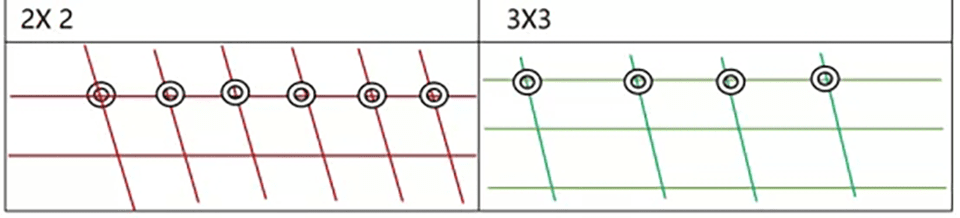

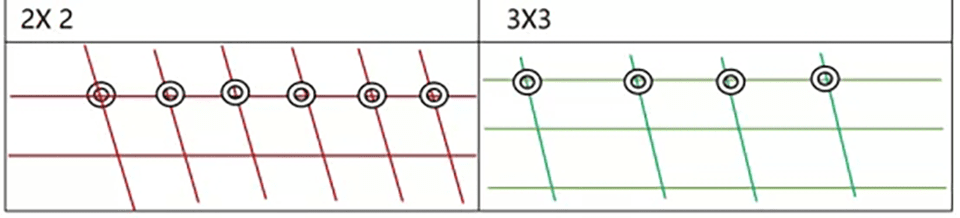

In addition, using 3x3 square opening, instead of 2X2, the hose is more flexible. For convenience of understanding, the following picture is drawn, showing the schematic diagram of the intersection points of the two braid processes at the same length:

There are far fewer intersections in 3x3 than in 2x2 for the same length. The spindle pull of 2X2 is 4-5 KGS and the spindle pull of 3x3 is 9 KGS. The compactness is better, and the variation range of production error is greatly reduced. So: in the case of 3X3 process, the hose is more flexible. The rate of hose defects has also been greatly reduced. At the same time, the pressure and impulse rate of the hose increased dramatically as the structure became tighter.

-

Improve atmospheric-resistance, prolong service life without increasing price

The ozone resistance of "Super Shield-flex" series hoses also shows "Super" superiority. When the hose works in a certain concentration of ozone for a long time, the cover layer is not easy to crack and oxidize. Under the standard test conditions, the ozone resistance time can reach 500 hours, far exceeding the standard 72 hours, which greatly improves the durability of the hose.

-

Improve ultraviolet resistance and low temperature -40 °C, and raise the temperature without increasing price

"Super Shield-flex" series is synthesized by adding imported raw materials with excellent anti-UV, anti-aging, low-temperature and thermal stability, which can well resist the influence of strong light and low-temperature environment and maintain good service performance.

-

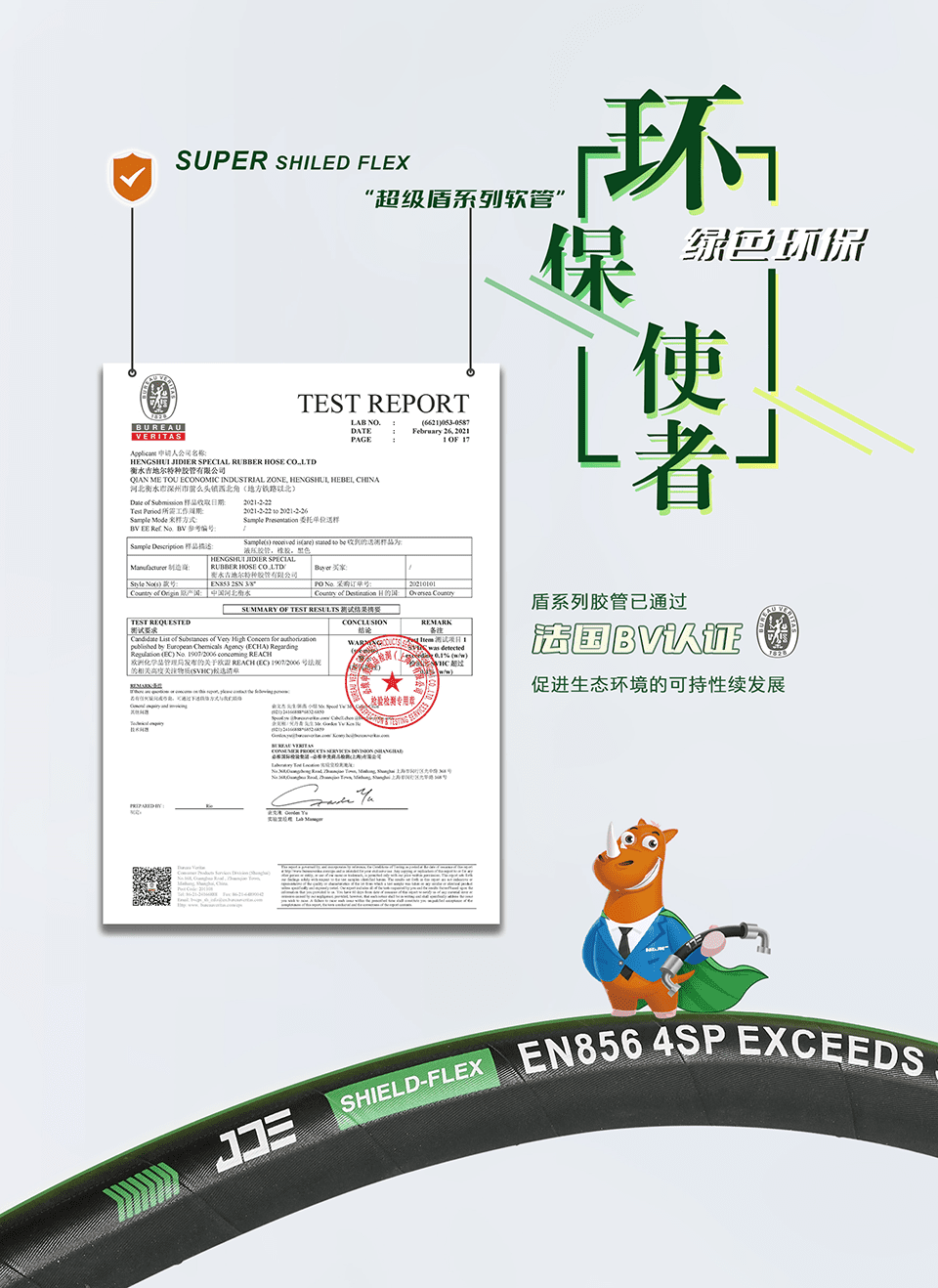

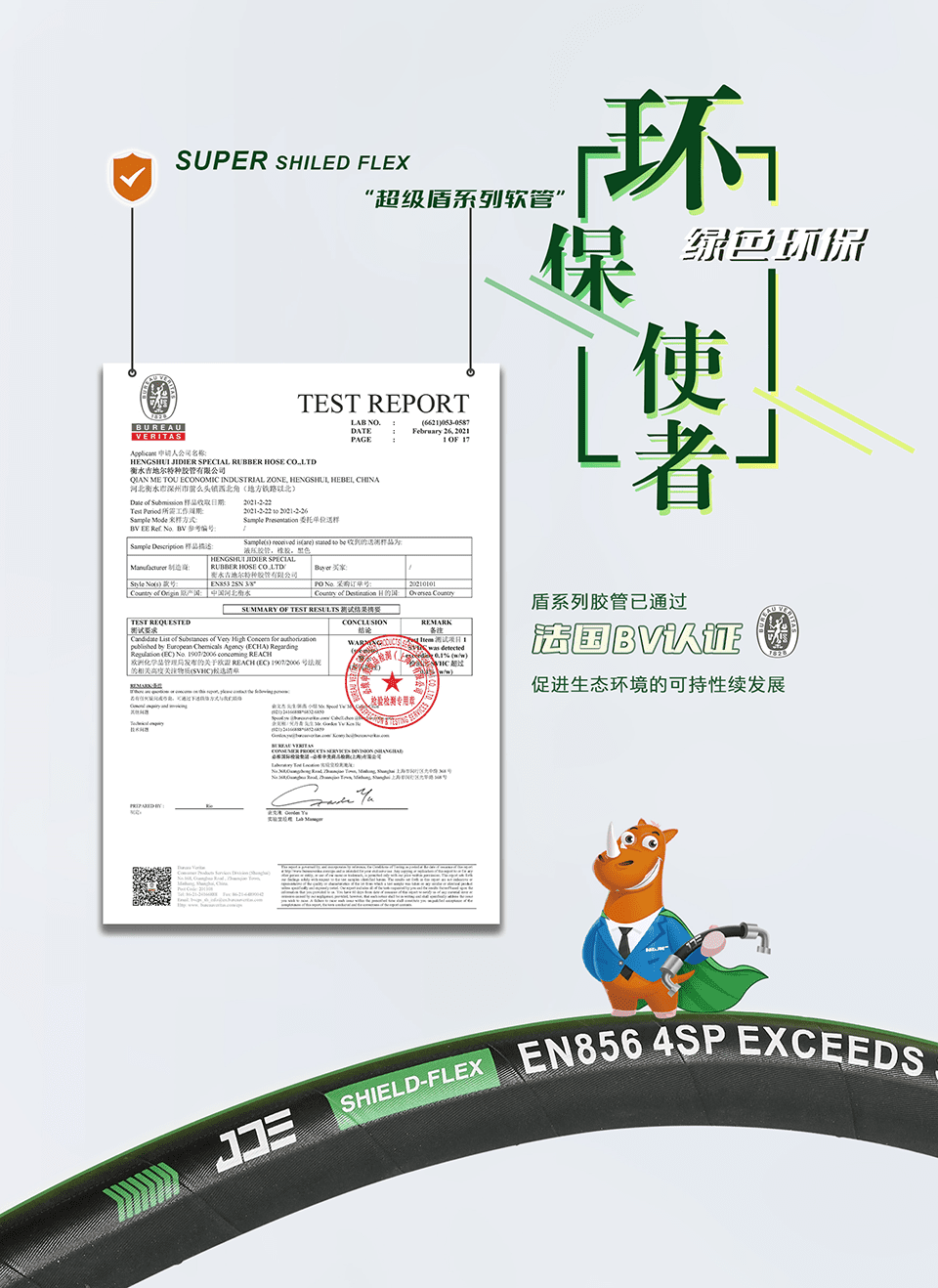

All passed BV test of French environmental protection

All passed the French environmental production BV test, does not contain any recycled rubber material and pollution harmful substances. Reduce environmental pollution, inner layer using special raw material synthesis, reduce the transmission rate of fluid medium.

With high-quality materials and advanced German equipment, "Super Shield-flex" series hose with super superior performance, far exceeding the industry standard. Continuously improving the quality and stability of products is the direction we have been pursuing and exploring. The promotion of "Super Shield-flex" series hose to standard hose standards is the new embodiment of our direction. DME&JDE group "Super Shield-flex" series hose "increase quantity without increasing price", we provide customers with more stable products, while maintaining the maximum rationalization of price. To our agents and customers to enhance greater profit space.

![Several different types of DME&JDE flexible hoses are displayed.]()

![Several different types of DME&JDE fluid connector are displayed.]()

English

English 简体中文

简体中文