November 18, 2021

DME Hydraulic Hose Fittings Introduction – Ferrule, Nipple & Sealing Modes

Previously, Mr.Niu Niu introduced the types and marking methods of DME hose fittings. In this issue, we will elaborate on the components of DME hose fittings.

Hydraulic hose assemblies use hydraulic hose fittings to connect hoses for hydraulic fluid transmission, which is crucial to the overall efficiency and safety of hydraulic systems. Factors to consider when selecting hydraulic hose fittings include the style of hose ferrules and nipples, nipple sealing methods, bending degree, and threads. Let's follow Mr.Niu Niu to learn more.

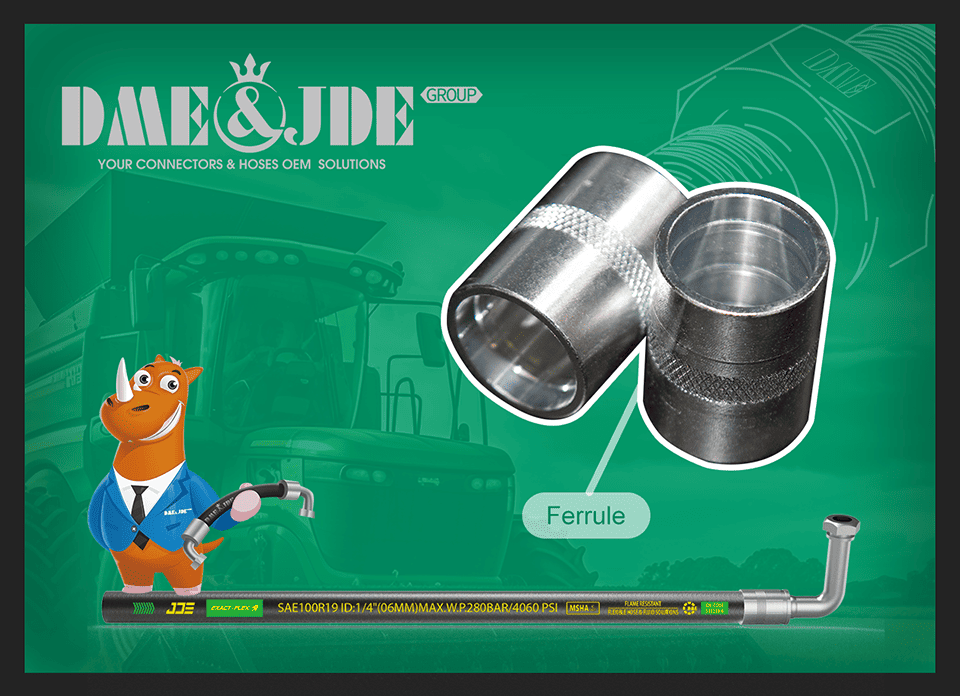

DME Hose Ferrule

Material, Type and Characteristics of DME Hose Ferrule

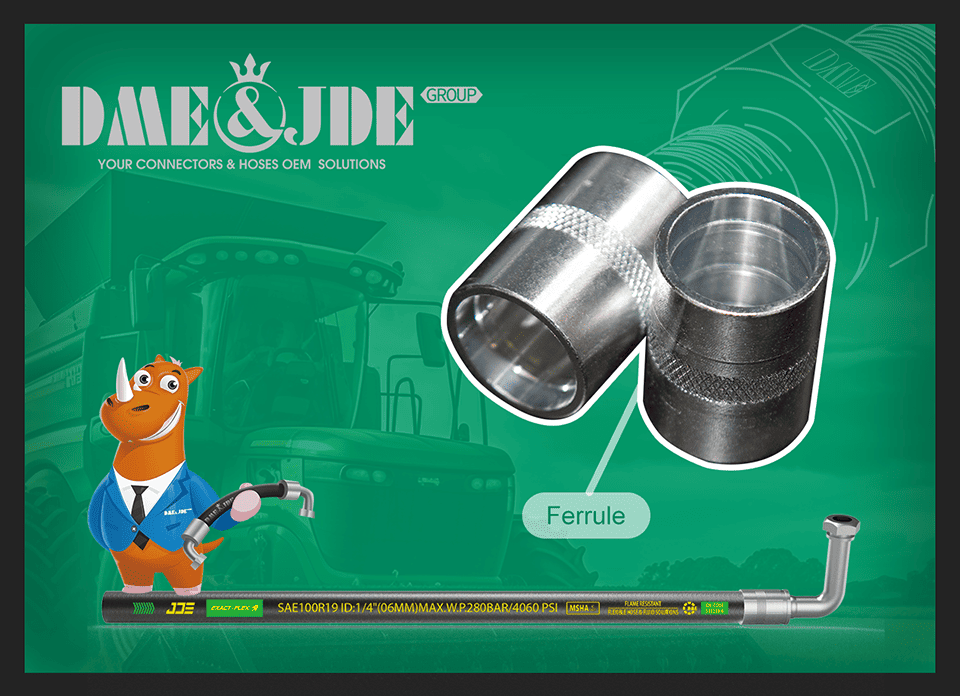

The hose ferrule is made of 20 steel, utilizing the material's good plastic deformation to enable the outer teeth to squeeze the rubber hose and form a sealed fit with the nipple. There are various types of ferrules, with different structural forms designed for different nipples, working environments, and specific operating conditions. The inner side of a ferrule typically features grooves or teeth, such as square grooves, trapezoidal or zigzag patterns, which need to be used in conjunction with corresponding nipple forms.

The commonly used structural types of ferrules can be roughly divided into the following three categories:

-

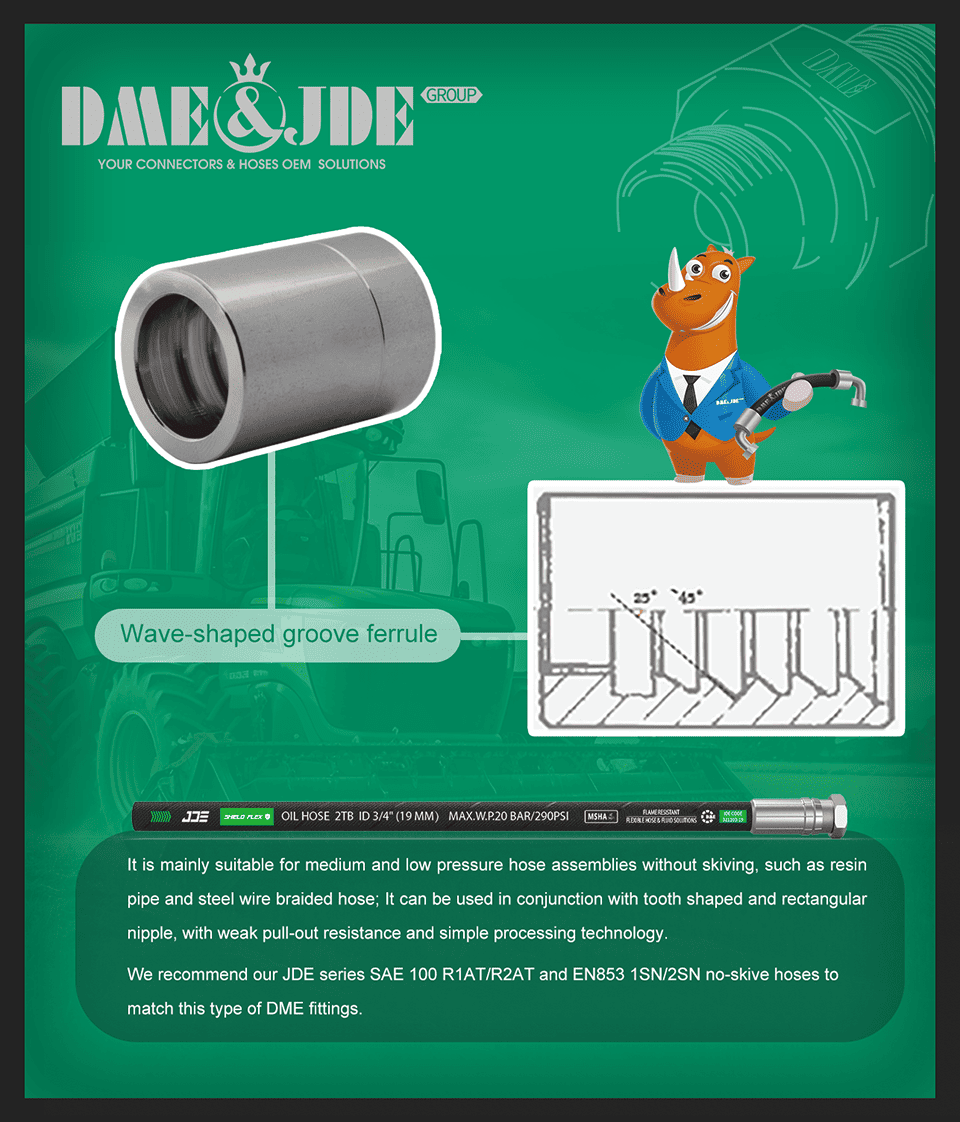

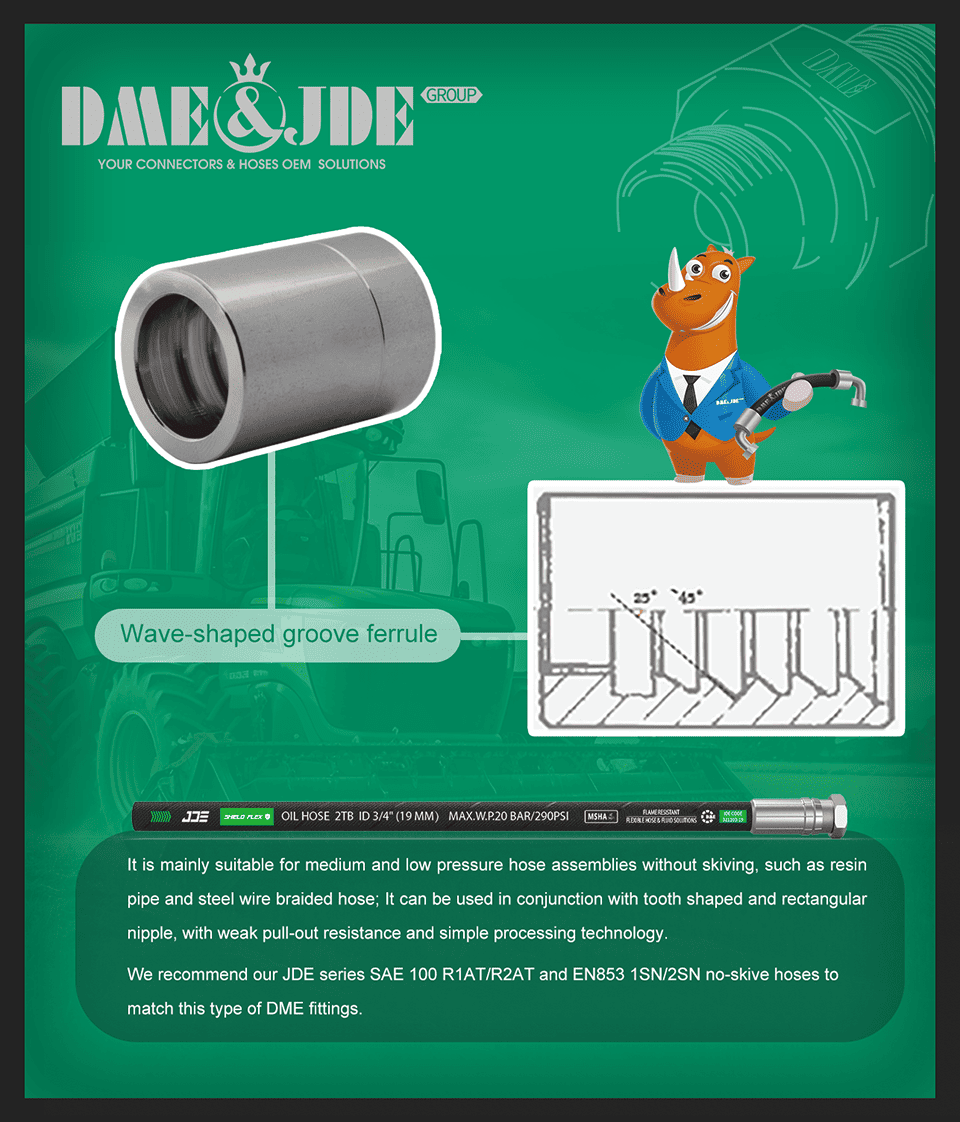

Wave-Shaped Groove Ferrule

The outer surface of the wave-shaped ferrule is mainly a smooth cylinder; the angle between the hypotenuse of the inner teeth and the axis is 25°–45°, and the radial edge and hypotenuse are connected by a fillet of 0.2–0.5 mm. It generally consists of 3–5 inner teeth.

-

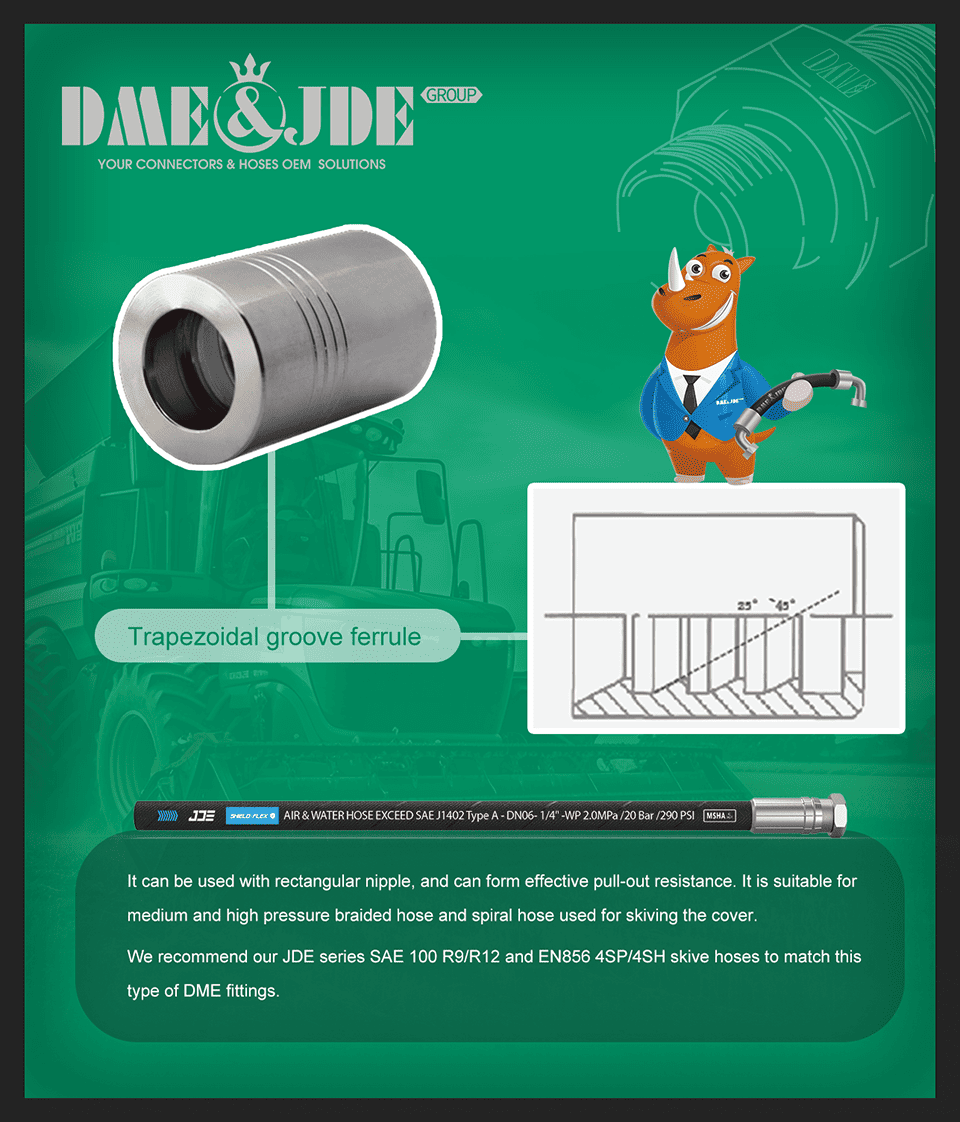

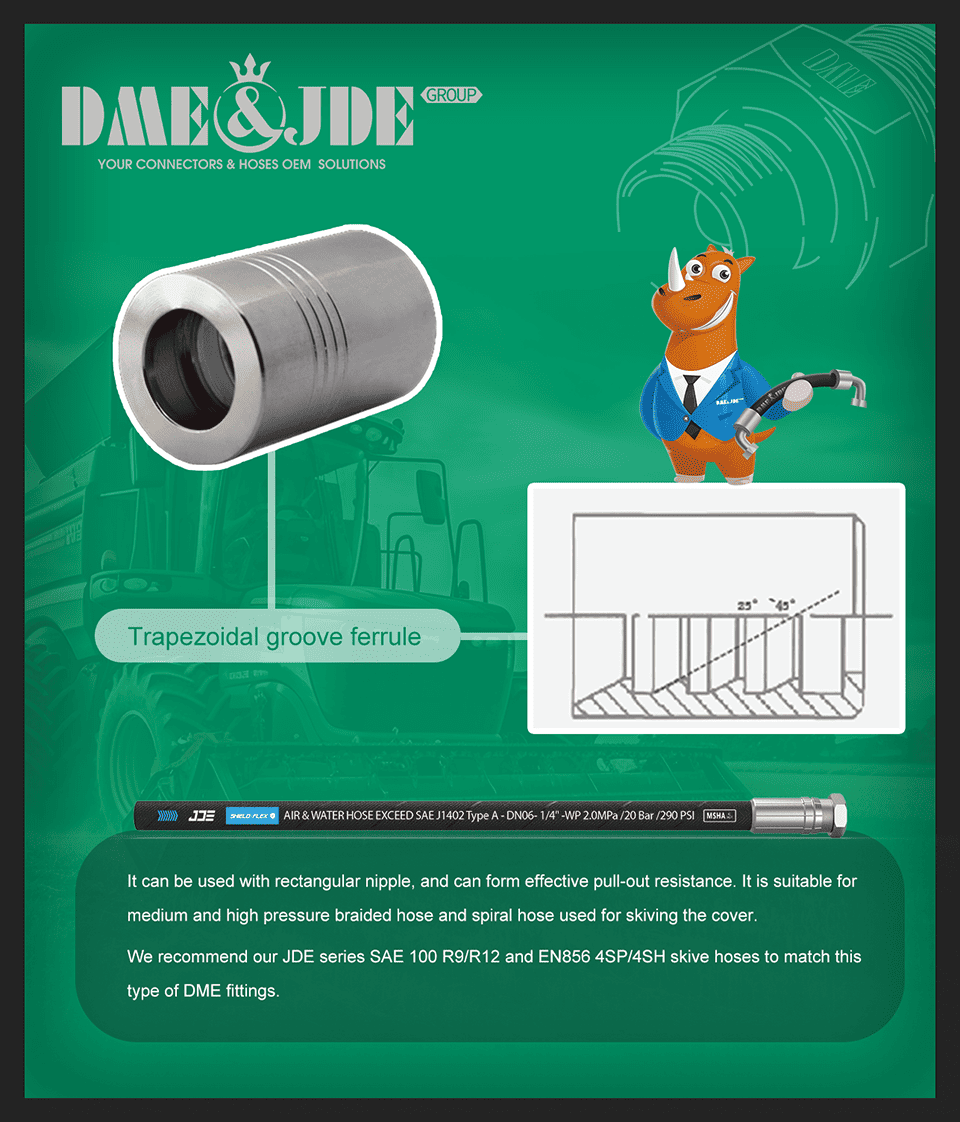

Trapezoidal Groove Ferrule

The outer surface is a smooth cylinder, and the inner surface has a certain number of trapezoidal gullets. The angle between the hypotenuse and the axis is 25°–45°, with a rectangular groove between each sawtooth. The top of the tooth is a plane 1–2 mm wide, and the tax corner is transitioned with a 0.2 mm fillet.

-

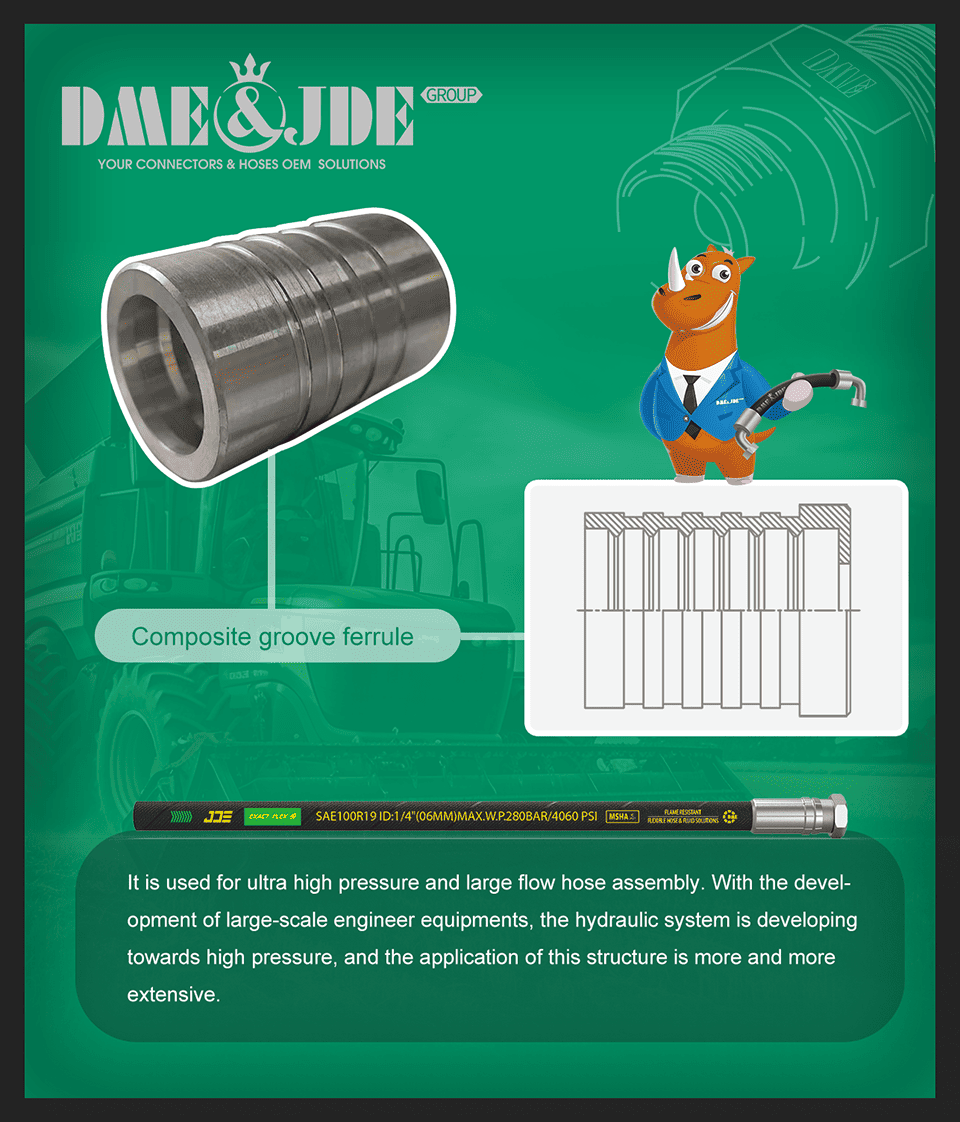

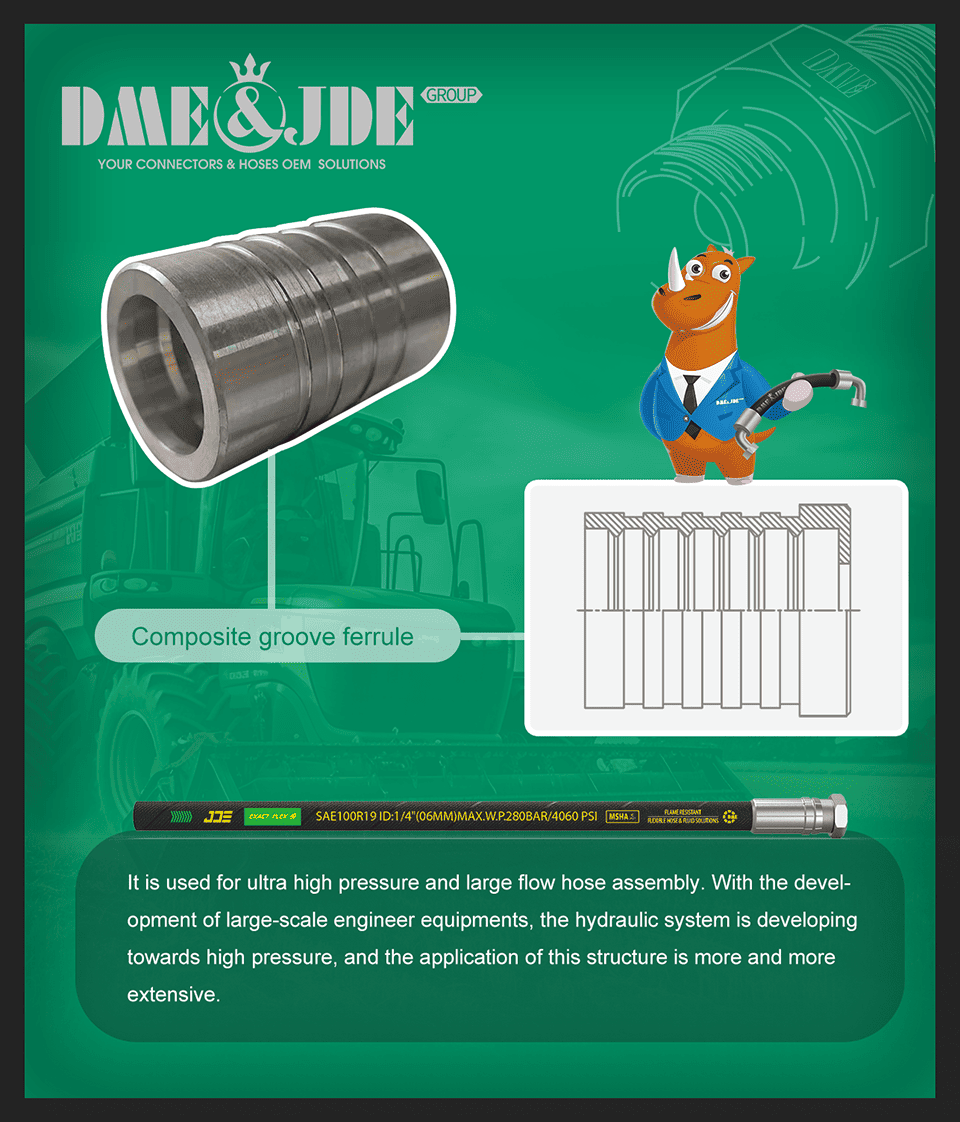

Composite Groove Ferrule

The outer surface features a T-shaped groove corresponding to the dislocation of the inner teeth, and the inner surface has a certain number of bilateral trapezoidal tooth grooves, suitable for matching with interlock nipples.

-

Ring-Shaped Ferrule

Besides the common ferrule types mentioned above, there are also some unique structures. As shown in the figure, the ring-shaped ferrule, unlike traditional ones, does not have different internal teeth machined inside; instead, it adopts a separate "ring structure" design, which is locked in the ferrule through extrusion, thus reducing processing costs. Its structural design is ingenious and achieves the same effective result.

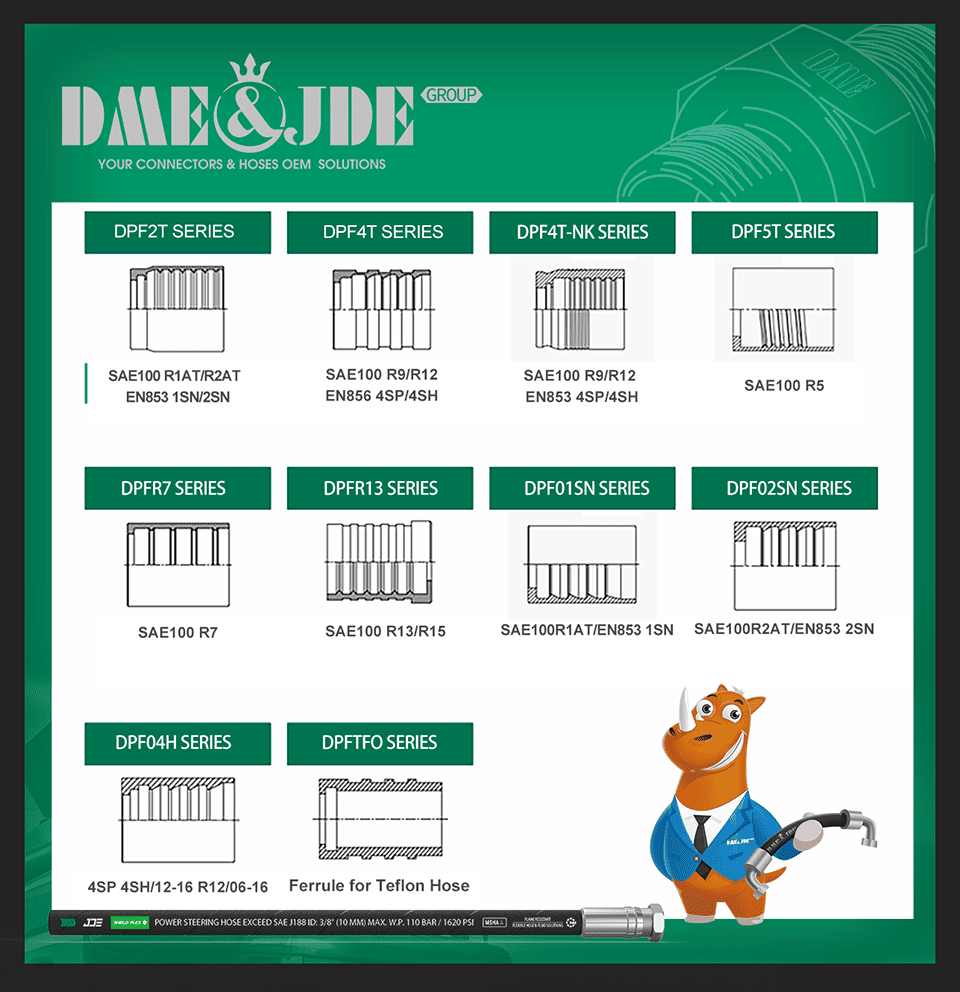

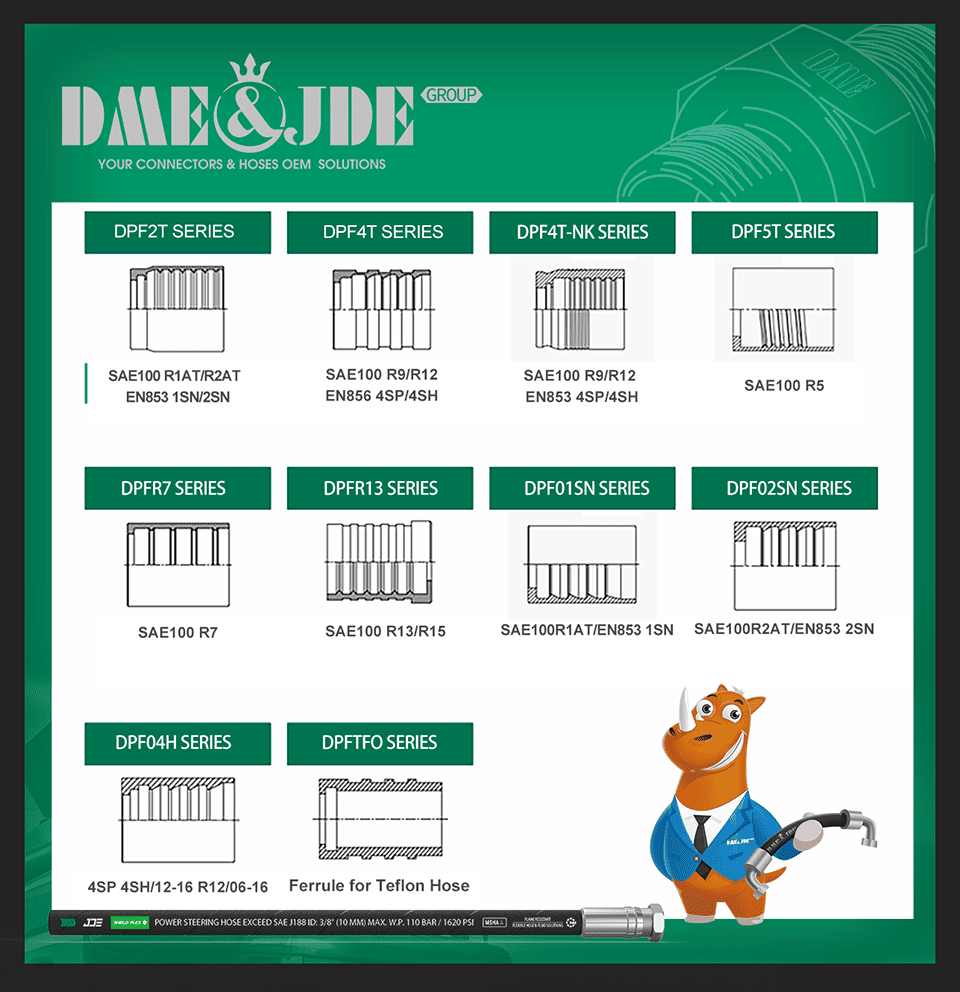

Selection of DME Hose Ferrule

The types of DME hose ferrules are shown in the following figure. Users can select appropriate hose ferrules according to actual production requirements.

DME Nipple Style And Sealing Mode

DME Nipple Material, Nipple Body Style

Common materials for nipples are 20, 35, and 45# steel. Straight nipples are often made of 35 and 45# steel, which have strong deformation resistance. Considering the bending process for bent nipples, 20 or 35# steel is generally chosen. With the popularization of hot bending technology, 35 and 45# steel can also be used for elbow nipples. The structural characteristics of nipples are closely related to the crimping form of the hose, and structures designed by various enterprises vary. Based on structural regularity, nipple types can be roughly divided into saw-tooth, rectangular, and interlock structures, etc.

-

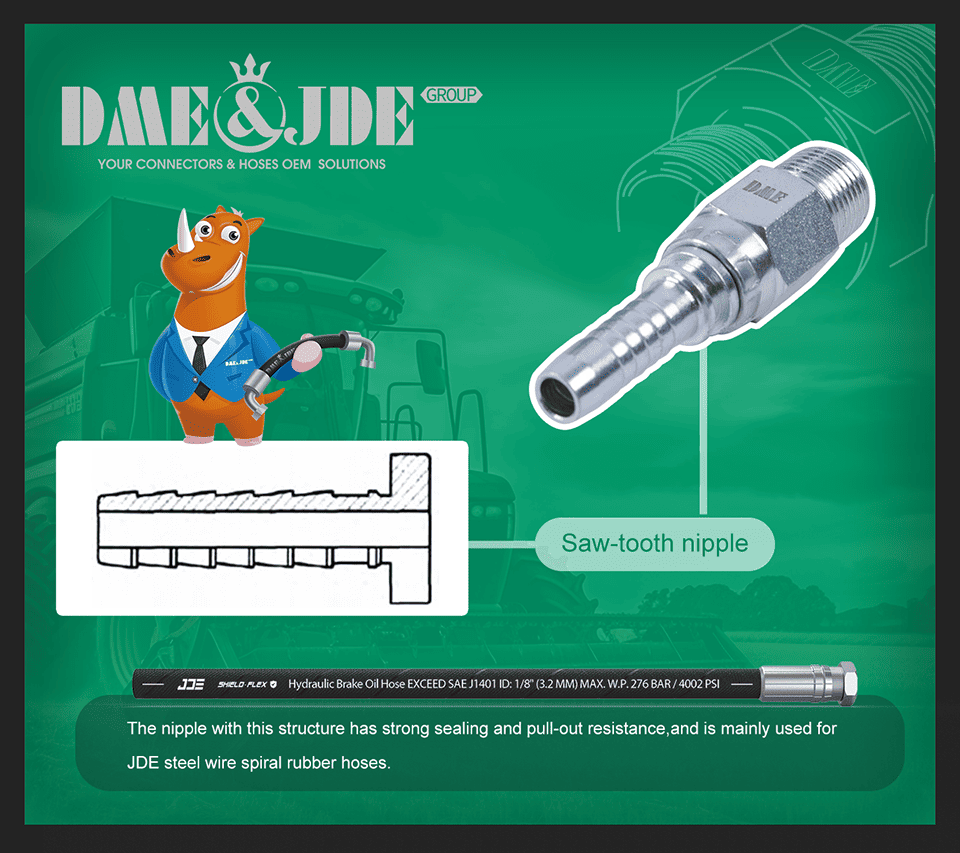

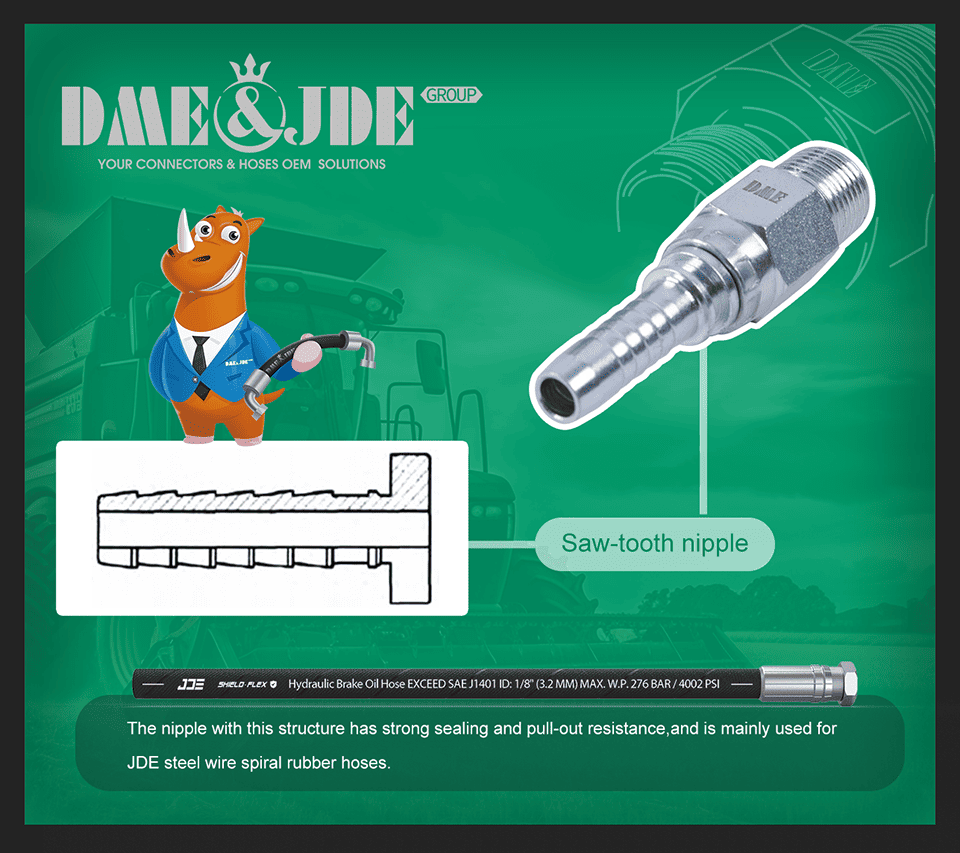

Saw-Tooth Nipple

Commonly known as barb-shaped. It is mainly composed of saw-tooth grooves; the angle between the bevel and the axis is generally no more than 20°, and the top of the sawtooth is circular or flat. The flat and short sides of the teeth are smooth rounded corners (0.2–0.5 mm) to prevent damage to the inner layer of the rubber hose during assembly and crimping.

-

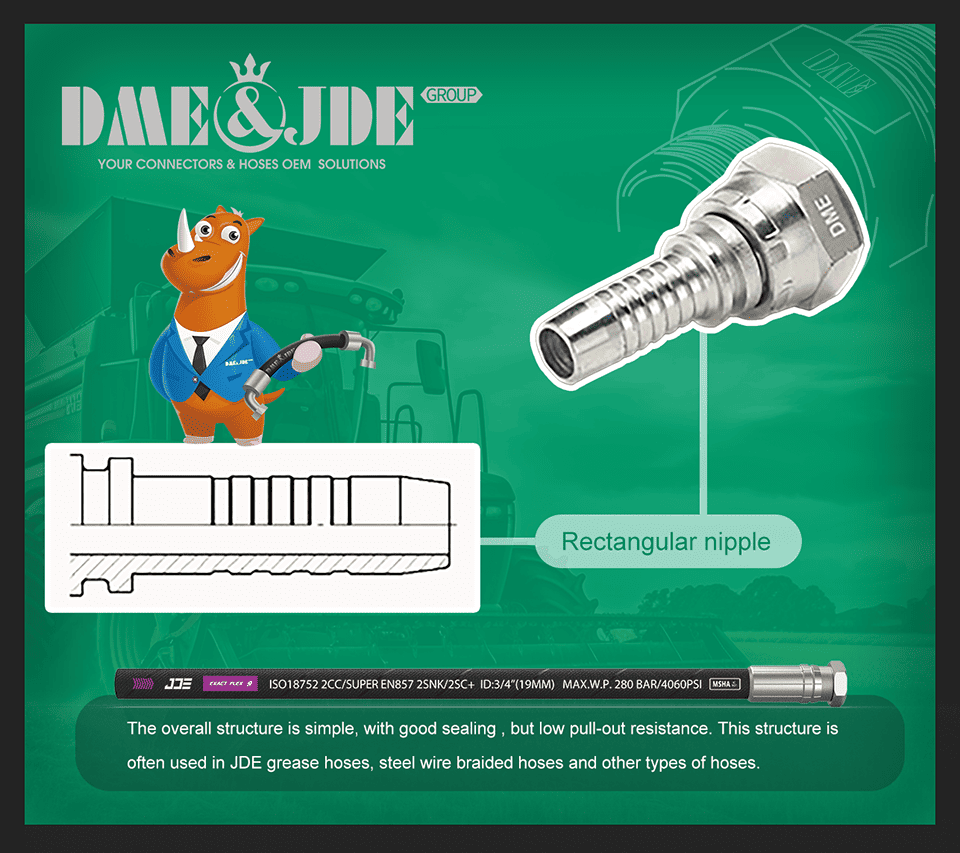

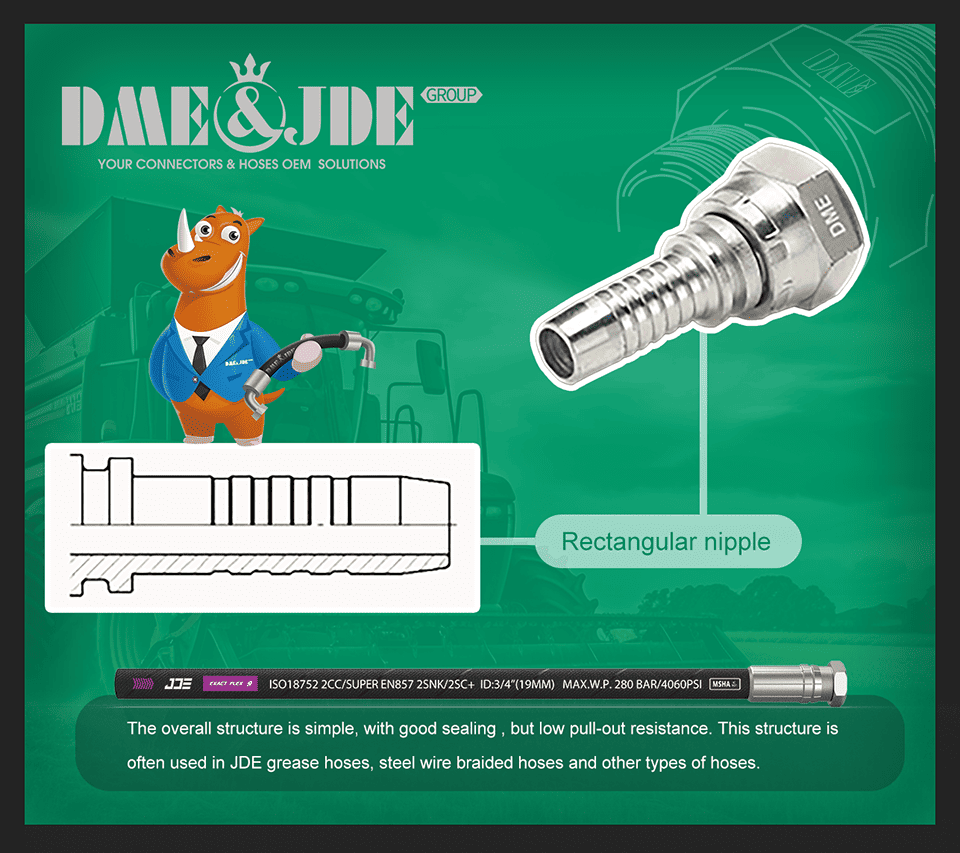

Rectangular Nipple

It is mainly composed of several rectangular grooves, with 5–7 grooves forming a sealing groove. The groove depth is generally 0.3–0.6 mm, and the transition surface between the groove top and groove bottom is generally a smooth rounded corner with a radius of 0.1–0.3 mm, so as to prevent damage to the inner layer of the rubber hose during assembly and crimping.

-

Inter-Lock Nipple

Also known as an anti-pull-out structure. This type of structure is specially designed to prevent the hose from being pulled out of the hose fitting, with sealing guaranteed by a rectangular structure. Thus, the interlock nipple is actually a fusion of the anti-pull-out structure and the rectangular structure.

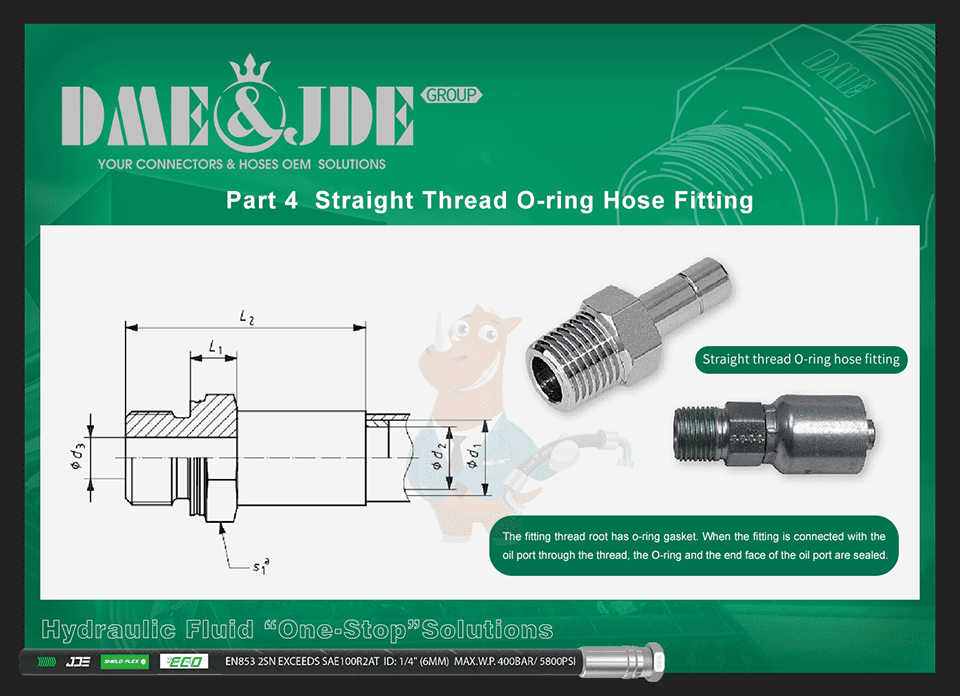

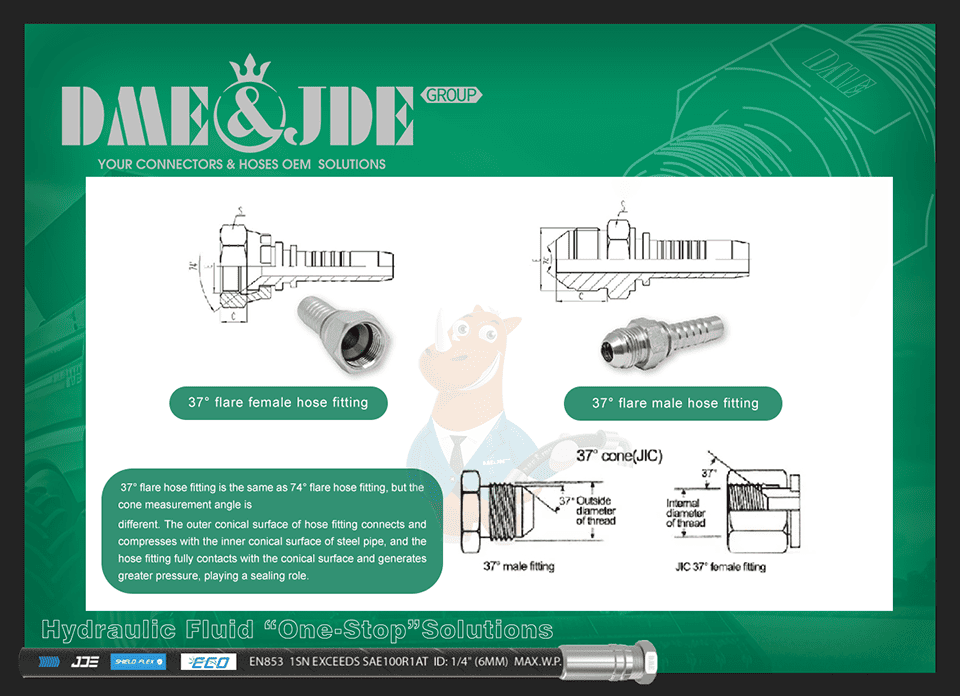

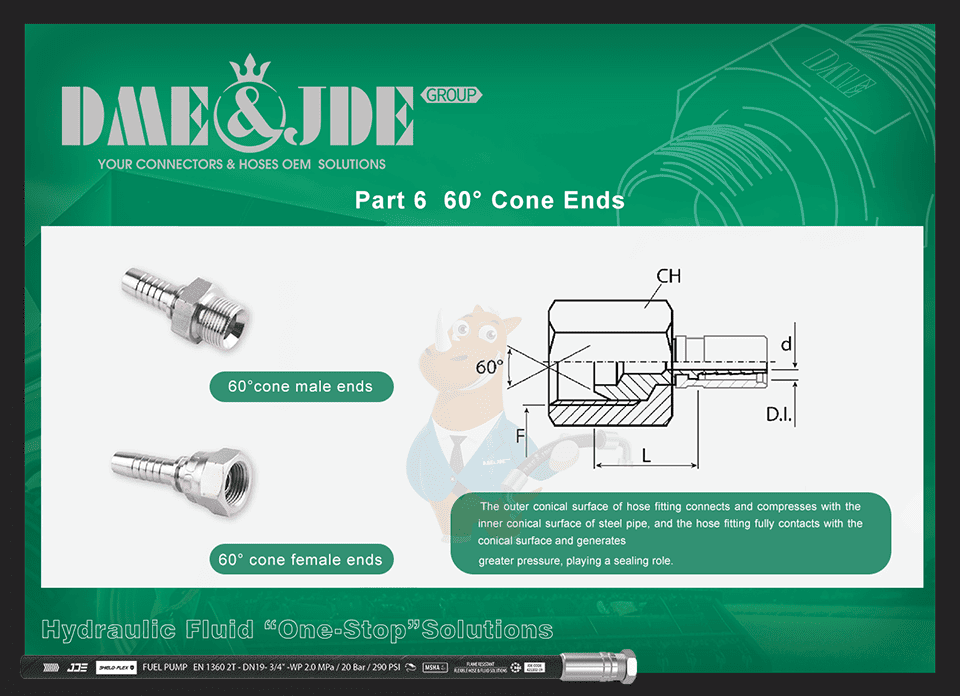

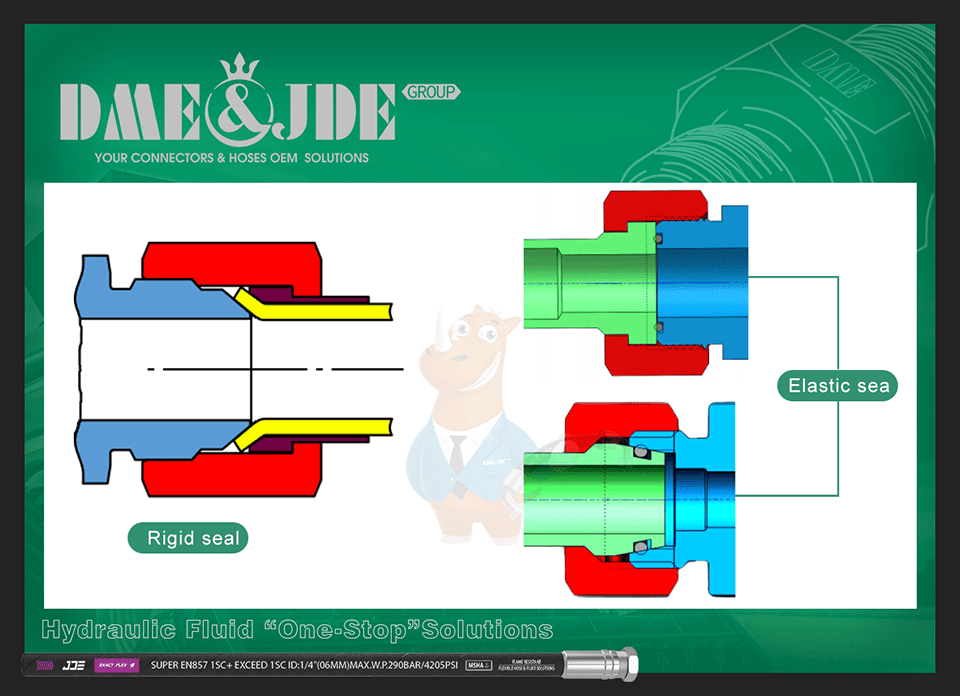

Sealing Mode of DME Nipple

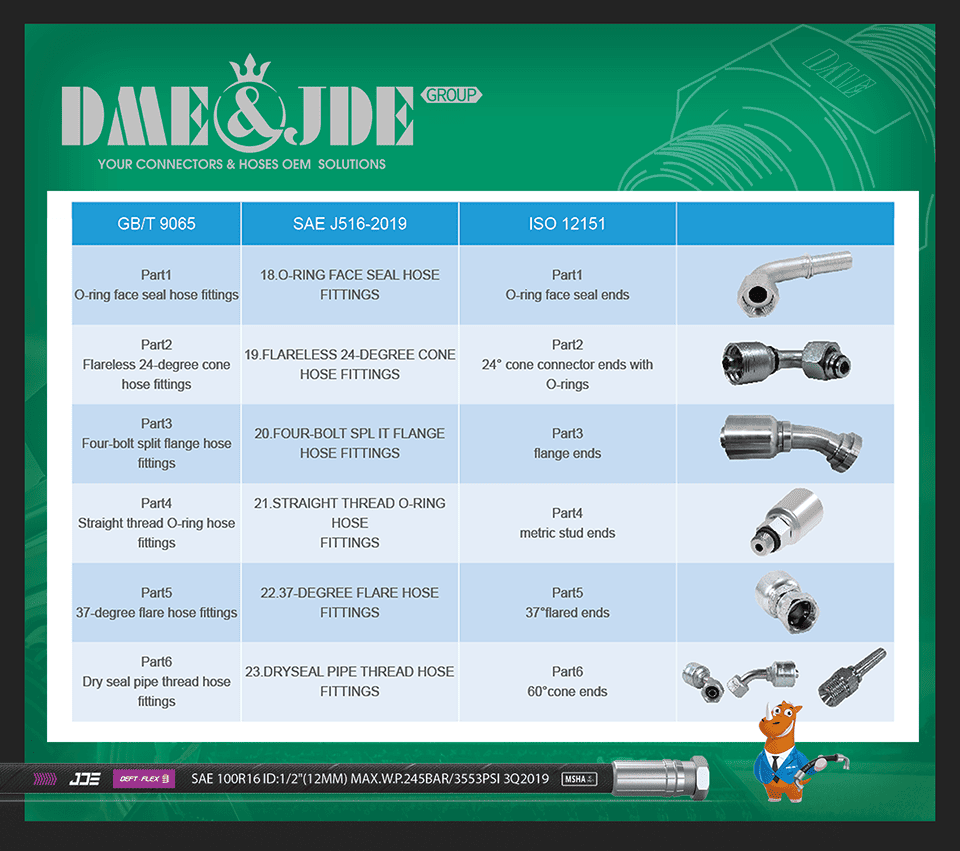

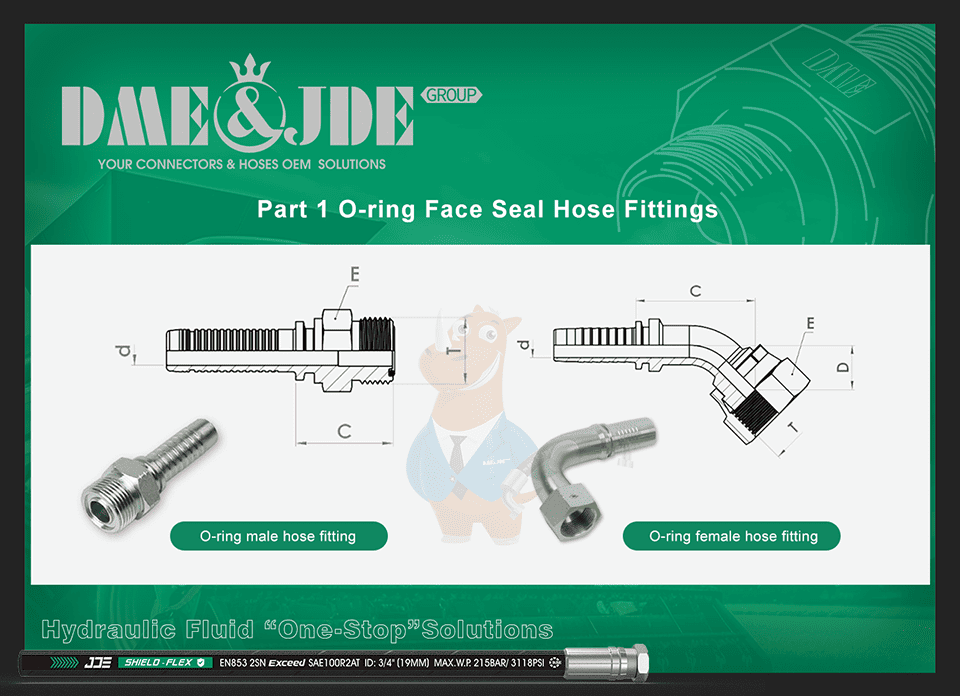

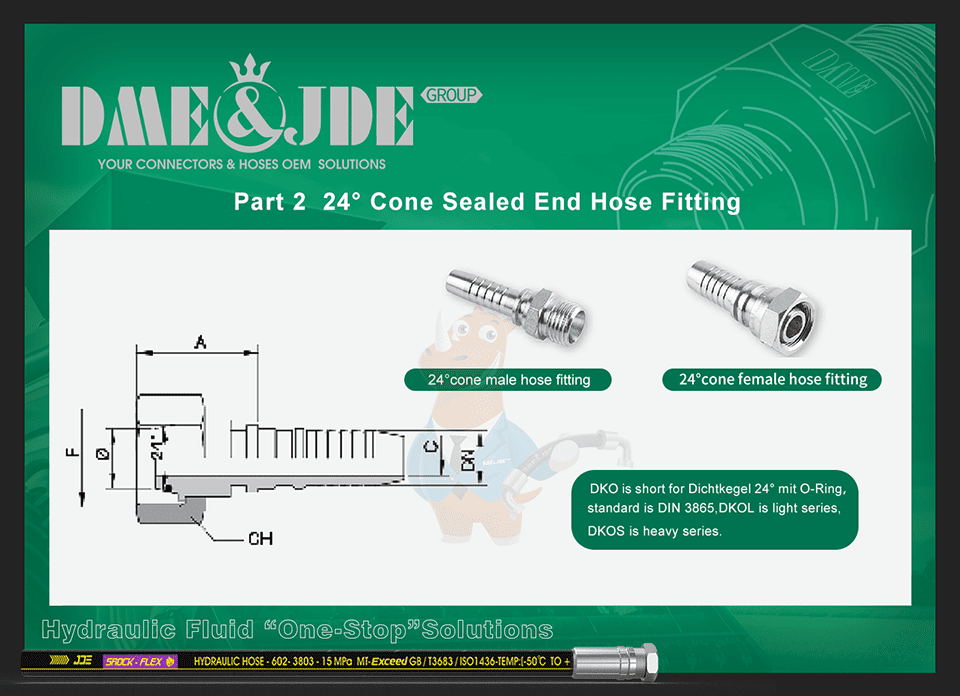

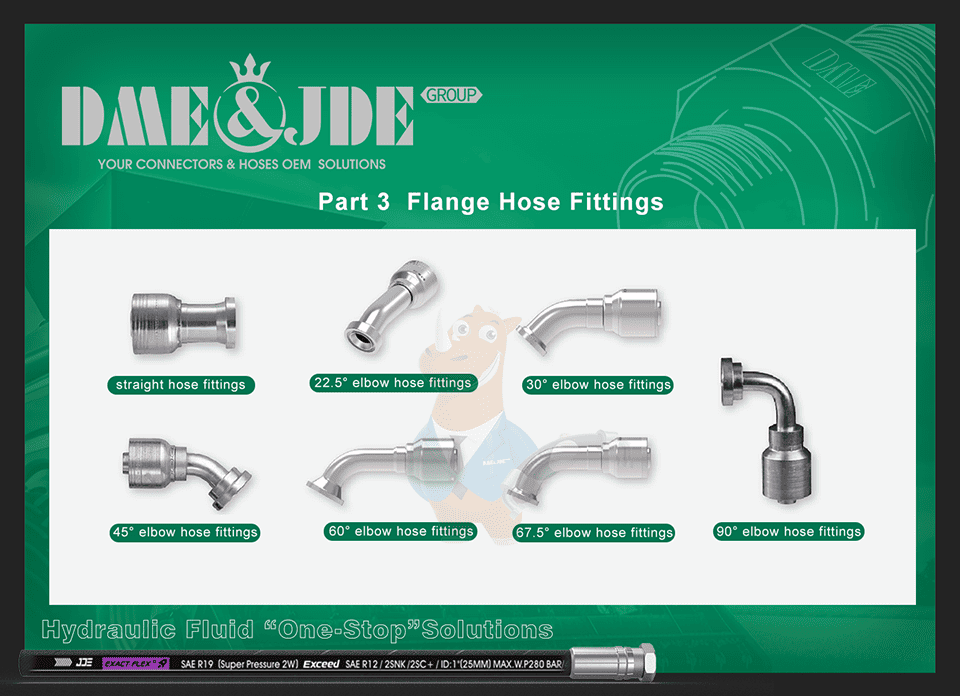

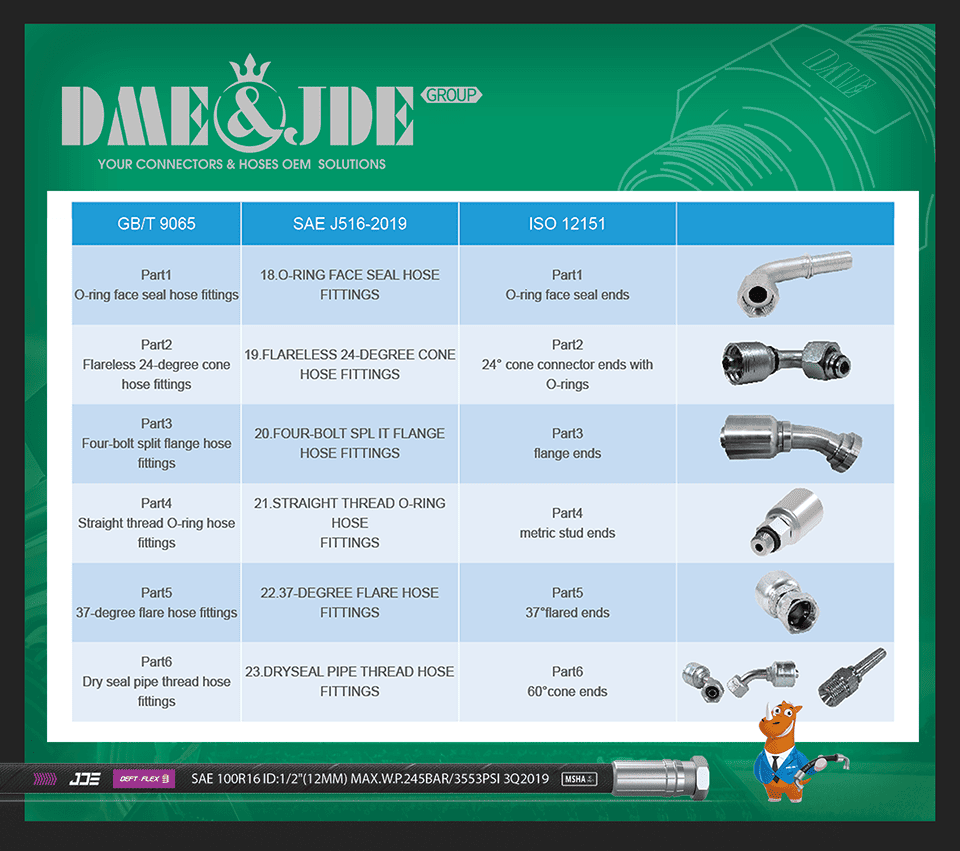

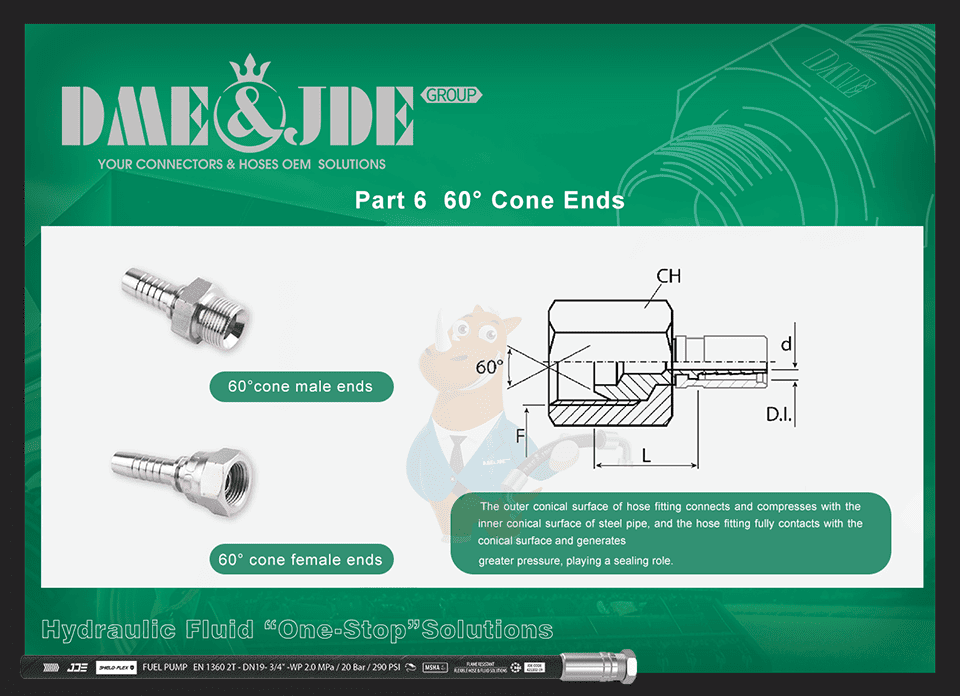

A comparison of hose fitting standards GB/T 9065, SAE J516-2019, and ISO 12151 shows that GB/T 9065 and ISO 12151 are basically the same in classification and description. When compared with SAE J516-2019, only Part 6 of SAE J516-2019 differs: one covers 60° cone ends, the other dry seal pipe thread hose fittings. (The specific features of DME nipples will be introduced by Niu Niu next time.)

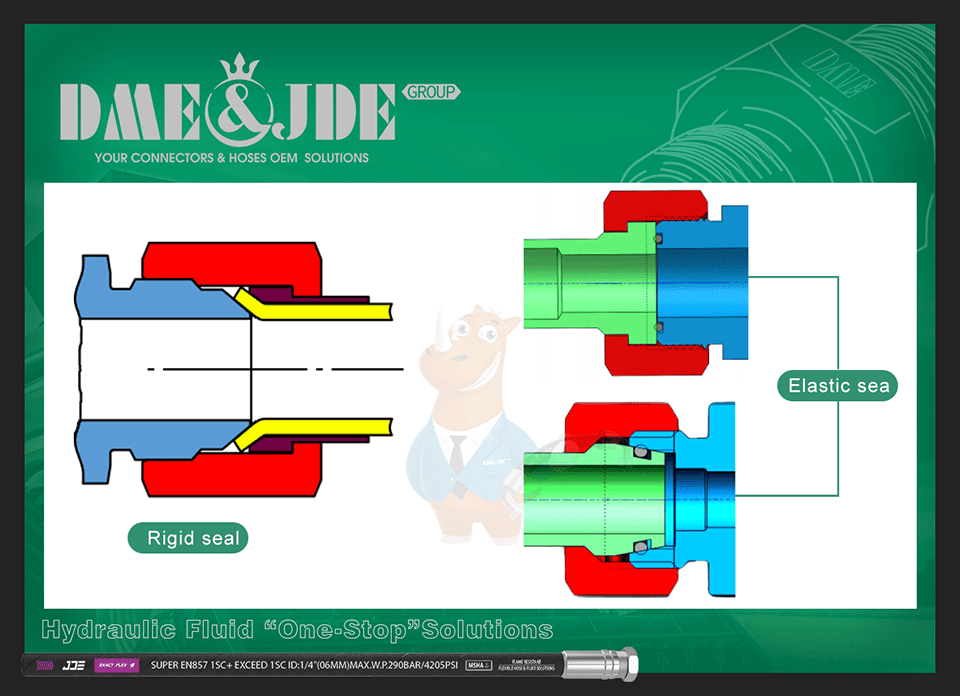

Sealing Mode of DME Hose Fittings

Other Types of DME Fittings

In addition to the above-mentioned types, there are still various types of fittings: 45° cone, 30° cone, 12° cone hose fittings, etc.

Besides straight hose fittings, there are also various elbow fittings: 22.5° elbow, 30° elbow, 45° elbow, 60° elbow, 90° elbow, etc. Companies should select the appropriate fitting style and elbow according to their specific production conditions.

We, DME&JDE Group, provide users with comprehensive and high-quality hoses, fittings, and accessories. We continuously optimize production equipment and design schemes to enhance product performance. Higher working pressures of hydraulic systems, faster speeds, and more compact assembly spaces are the directions we constantly strive for!

For more product information, please log in to our official websites:

![Several different types of DME&JDE flexible hoses are displayed.]()

![Several different types of DME&JDE fluid connector are displayed.]()

English

English 简体中文

简体中文