July 07, 2021

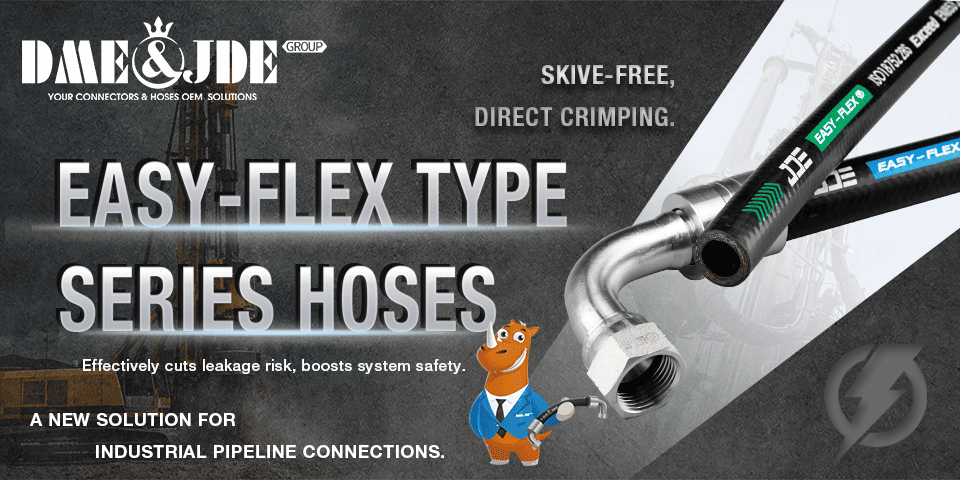

Easy-Flex Type Series Hoses Let People Use The Real American Standard Products Without Skiving

In hose connection systems, the crimped joint between the hose and fitting is the core determinant of assembly tightness. Our peel-free hoses and fittings are precisely matched: once connected, the sleeve and hose form a tight interlocking structure, akin to a "safety armor" for the pipeline. This unique design not only eliminates leakage risks but also prevents rubber accumulation, ensuring the hose assembly maintains stable and reliable sealing performance and smooth operation during long-term, high-intensity use.

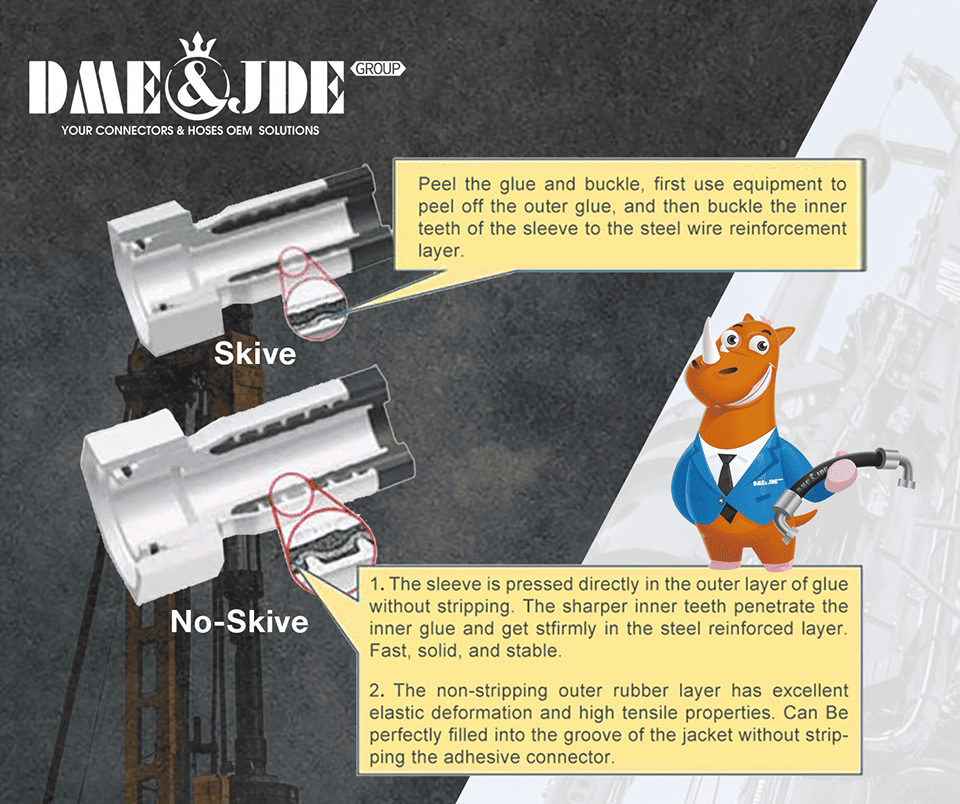

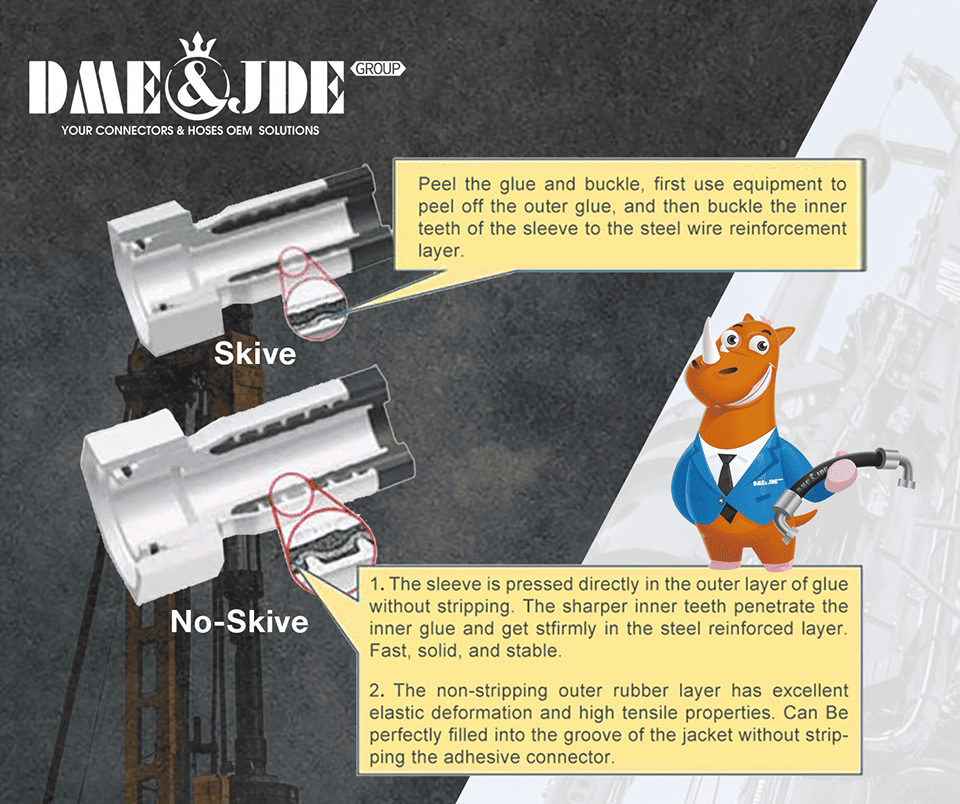

Traditional Skive Crimping VS Easy-Flex No-Skive Crimping

For traditional rubber-stripped hose assemblies, before connecting the fitting to the hose end, tedious procedures are required, including measuring the crimping dimension, using rubber-stripping equipment to remove the outer rubber layer at the hose end, crimping, re-measuring, and cleaning, which results in low crimping efficiency.

The EASY-FLEX series hose assemblies are a perfect combination of JDE Easy-Flex non-rubber-stripping hoses and DME Easy-Fit one-piece crimping connectors, covering both braided and spiral hoses. This series eliminates the need for rubber stripping and allows direct crimping on the outer rubber layer of smooth-surface hoses, simplifying the operation process and significantly improving crimping efficiency!

Crimp Connector Internal Structure

Below to give you a more intuitive display the withholding internal structure of stripping hose and non-stripping hose.

What Makes Easy-Flex Type Series Hoses Free From Skive Crimping?

-

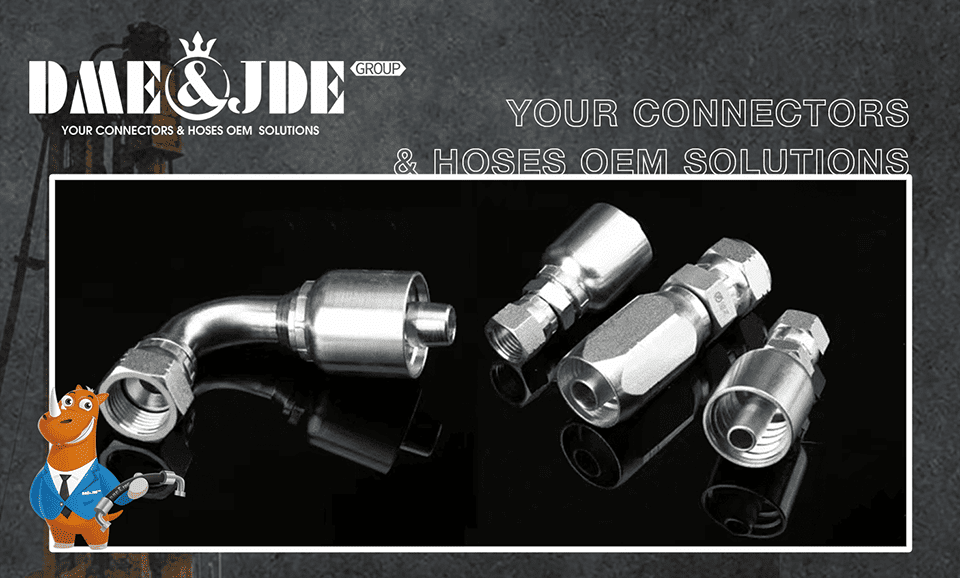

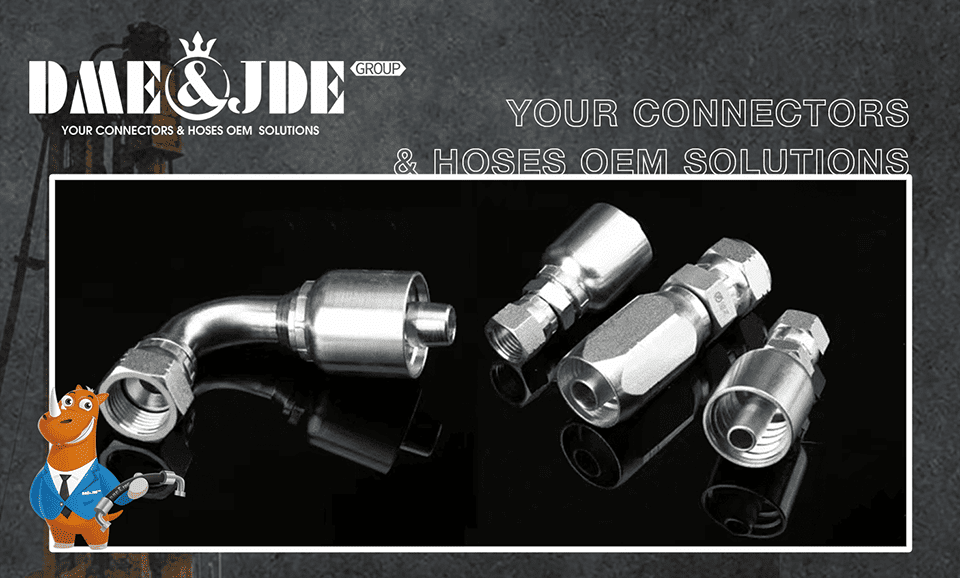

DME One-Piece Crimping Hose Connector @Easy-Fit

The EASY-FLEX series non-rubber-stripping hose connectors adopt DME one-piece crimp connectors, featuring precise dimensions and corrosion resistance. No rubber stripping is required during crimping, offering strong versatility and convenient operation. Meanwhile, they have excellent sealing performance to effectively prevent oil leakage.

The DME hydraulic connector production base is equipped with advanced German-style production machinery and equipment to ensure that each connector is manufactured to the standards of "high precision and accuracy", achieving perfect fit with JDE hoses and providing stable liquid transmission power for host equipment.

-

JDE developed external outer rubber @Easy-Type for "EASY-FLEX"

The outer rubber formula has been upgraded and reorganized. Laboratory data shows that the rubber content of braided hoses is 40%-45%, and that of spiral-wound hoses is 45%-47%. It has excellent tear resistance and rebound resilience. The outer rubber layer is thinner than other brands, with excellent rebound and filling performance, precise crimping, and joints that are not easy to slip. The outer rubber has excellent abrasion resistance, and the hose surface is smooth with low friction, which can reduce failures caused by friction between hoses during operation.

Advantages Of No-Skive Crimping Technology

The non-stripping crimping technology offers unparalleled advantages over traditional stripping methods:

- Streamlined crimping process with 30% higher efficiency;

- Prevents premature hose failure caused by under/over-stripping;

- Eliminates stripping step to protect reinforcement wires from damage;

- Secure interlocking between inner teeth of the fitting sleeve and outer rubber layer ensures excellent sealing performance and zero leakage.

Fast and reliable – that's our promise. Our non-stripping hose connection technology delivers exceptional convenience while eliminating leakage risks caused by under/over-crimping. It's the preferred choice for all hydraulic applications.

The EASY-FLEX series hoses provided by DME&JDE GROUP all adopt integrated non-stripping technology, with weather resistance exceeding 5 years and a 2-year quality guarantee. This significantly extends the service life of the hoses and helps users "reduce costs and improve efficiency".

![Several different types of DME&JDE flexible hoses are displayed.]()

![Several different types of DME&JDE fluid connector are displayed.]()

English

English 简体中文

简体中文