June 22, 2021

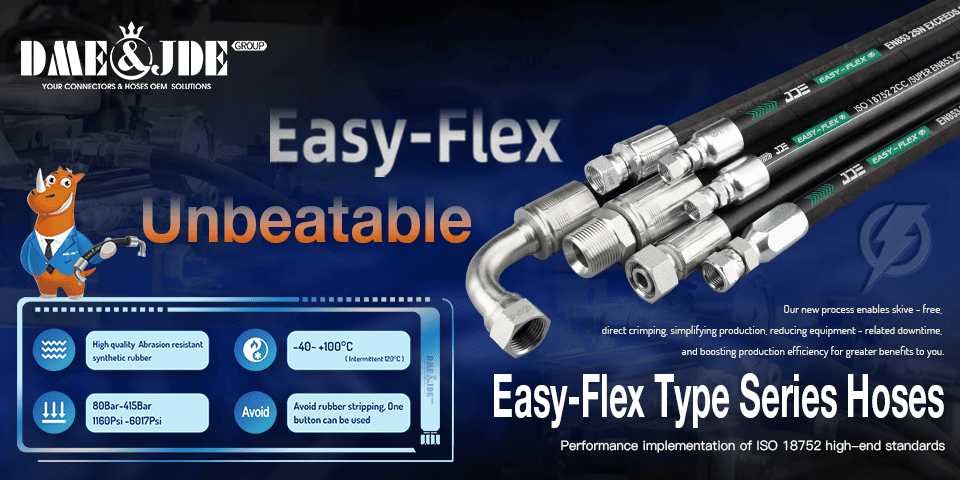

Easy-Flex Type Series Hoses, Reduce Downtime, Let The Host Double Work

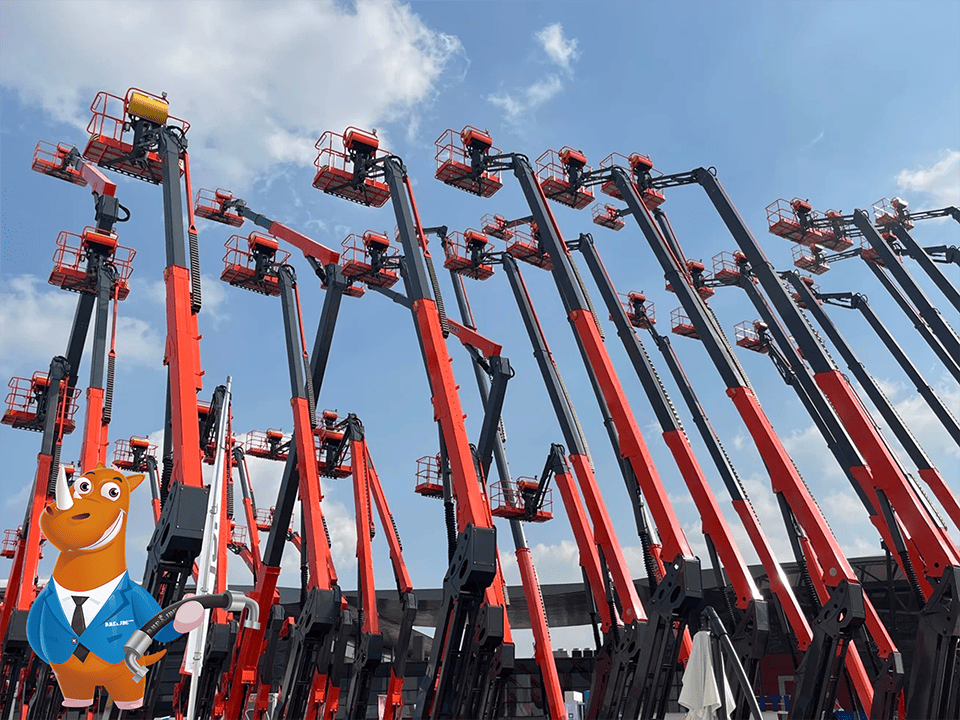

In this fast-developing society, time is money, the equipment in the main engine factory can work continuously, the downtime maintenance time is short, the maintenance interval time is long, can raise the production efficiency, obtains the maximum profit. However, hoses play a vital role in these devices, providing a constant source of power for mechanical devices. This requires the hose assembly with high pressure, heat resistance, good flexibility and other outstanding performance. So what kind of hose can carry such a burden?

Here, DME&JDE Group gives the answer:

Easy-Flex type series hoses.

Its performance is completely matched and even far better than that of the original equipment manufacturer. The new Easy-Flex type series hoses will make every dollar count.

- No-Skive, High Efficiency

When the joint is pressed, the complicated procedure of stripping glue is removed, and the pressing efficiency is increased by 30%.

- Fluid Compatible And Resistant To Corrosion

The internal hose is synthetic rubber, extruded in one piece, no joints, uniform thickness, suitable for the transport of a variety of fluids, such as: mineral Oil and bio-oil, ethylene glycol water-based, water, lubricants.

- Wear Resistance and Long Service Life

The rubber layer is made of anti-wear synthetic rubber and smooth hose to reduce the failure of hose due to friction.

- High Pressure Resistance, Reduce Blasting Accidents

Can withstand operating pressures of 80 bar – 415 bar / 1160 PSI – 6017 PSI, exceeding SAE 100R2A standard.

- High Pulse Resistance, Shorten Fatigue Cycle

Under 133% working pressure, pulse frequency of one-layer braided structure is 150,000 times, pulse frequency of two-layer braided structure is 200,000 times.

- Quality Assurance, Safety Assured

Hose through MSHA & BV & MA certified, accessories through DEKRA & IATF16949 & DAKKS & SGS certification

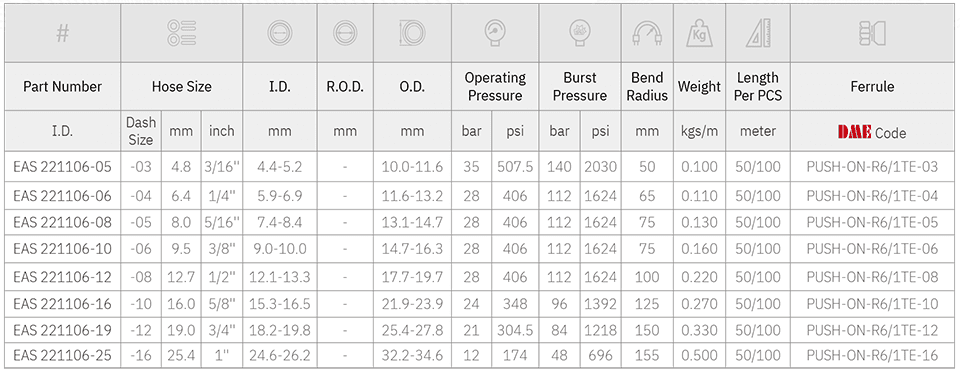

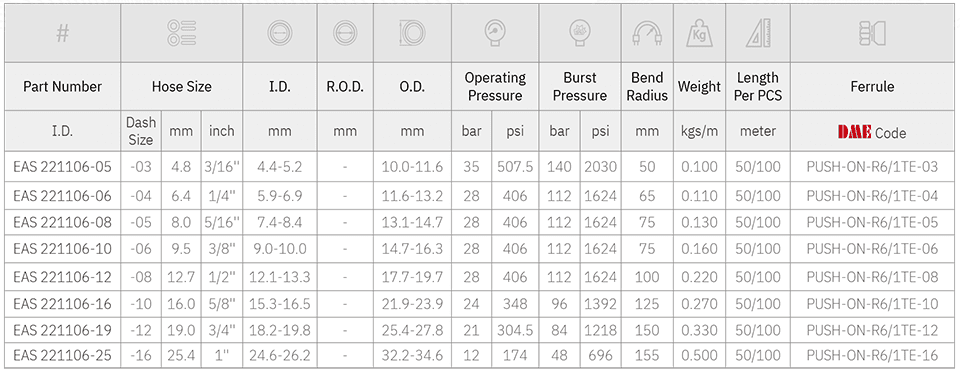

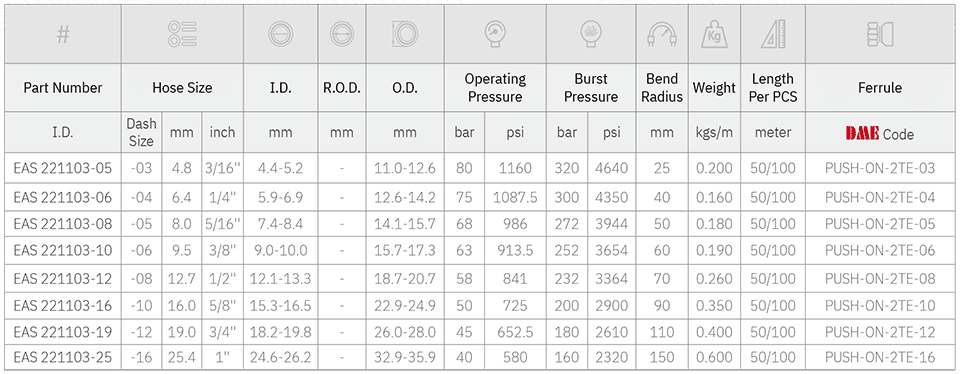

Easy-Flex Type Series Specification Sheet

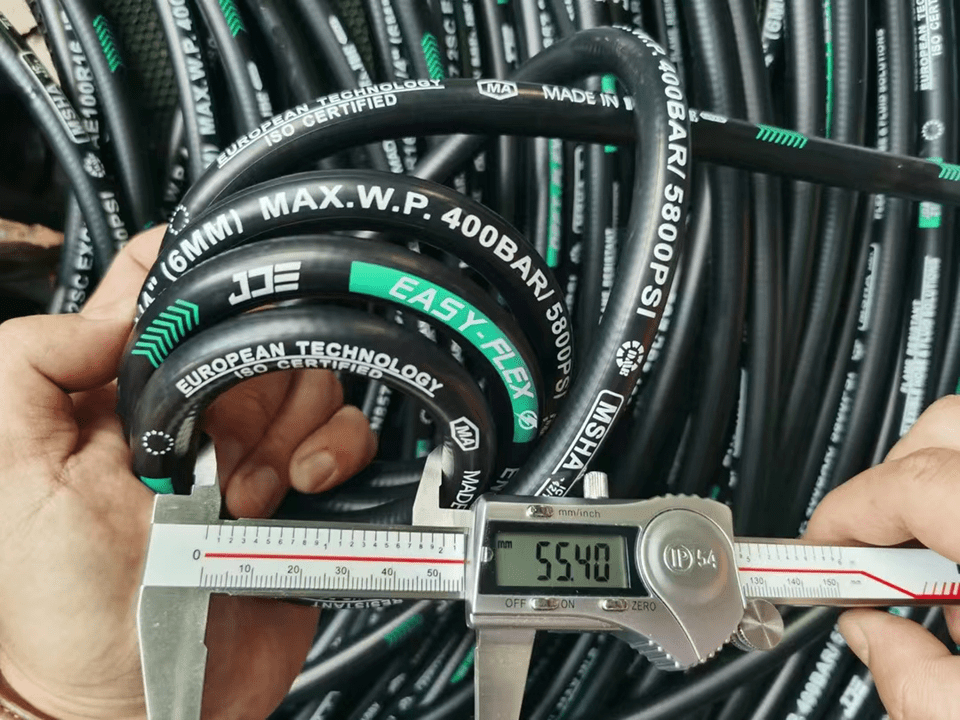

Easy-Flex Type Series Hoses Production Details

-

Easy-Flex type series hoses braiding reinforced layer adopts unique high-strength steel wire and German-style mechanical equipment braiding process, making the strength and density better than the traditional 2-layer steel wire braiding hose, strong bearing pressure, to meet the needs of most hydraulic systems.

-

Easy-Flex type series hoses adopt the rapid pressing process: Omitting the complicated peelings, pressing directly (the matching joint is DME series hose joint), the pressing efficiency is increased by 30%.

Easy-Flex Type Series Hoses Performance Test (According to ISO18752)

Each hose of Easy-Flex Type Series has been professionally and strictly tested to ensure better performance.

Next, we have carried out burst test, pulse test and bending effect display for Easy-Flex series hoses.

-

Blasting Test

We conduct bursting pressure test on the hose to ensure that each hose can be safely and effectively put into work, so that the staff can stay away from the collapse accident and work at ease.

-

Pulse Test

The Easy-Flex type series has no failure after hundreds of thousands or even millions of pulse tests.

ISO 18752 Impulse-Resistant Performance

| Grade |

Type |

Impulse-Resistant Performance |

|

|

Temperature(°C) |

Working Pressure (% of MWPb) |

Minimum Number Of Pulse Cycles |

| A |

AS |

100 |

133% |

200,000 |

| AC |

| B |

BS |

100 |

133% |

500,000 |

| BC |

| C |

CS |

120 |

133%

120% |

500,000 |

| D |

CC |

120 |

120% |

1000,000 |

| DC |

Remarks:

A: standard or compact hose, for example, CS represents grade C. Standard hose has a larger outer diameter and bending radius. Compact hose with smaller outer diameter and bending radius.

B: maximum working pressure.

C: Hose with pressure classes 350, 420 and 560, pulse pressure 120% of the maximum working pressure ISO 18752 hoses are classified into four classes according to their resistance to pulse. A, B, C and D, each class is further divided into standard (AS, BS and CS) and compact (AC, BC, CC and DC) according to outer diameter dimensions. |

-

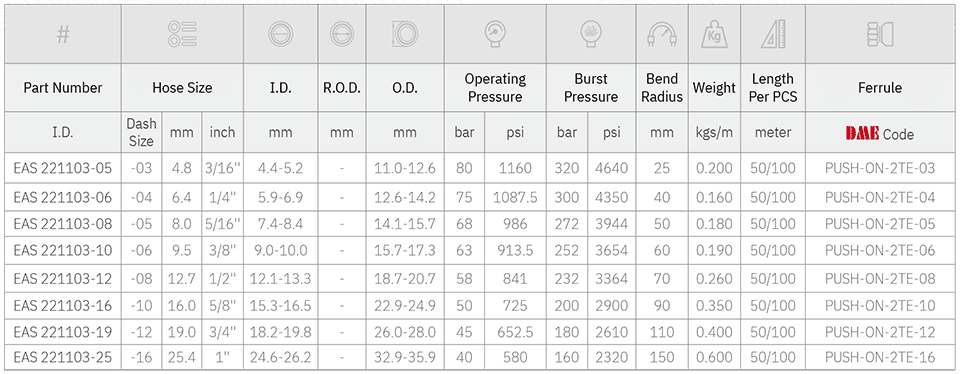

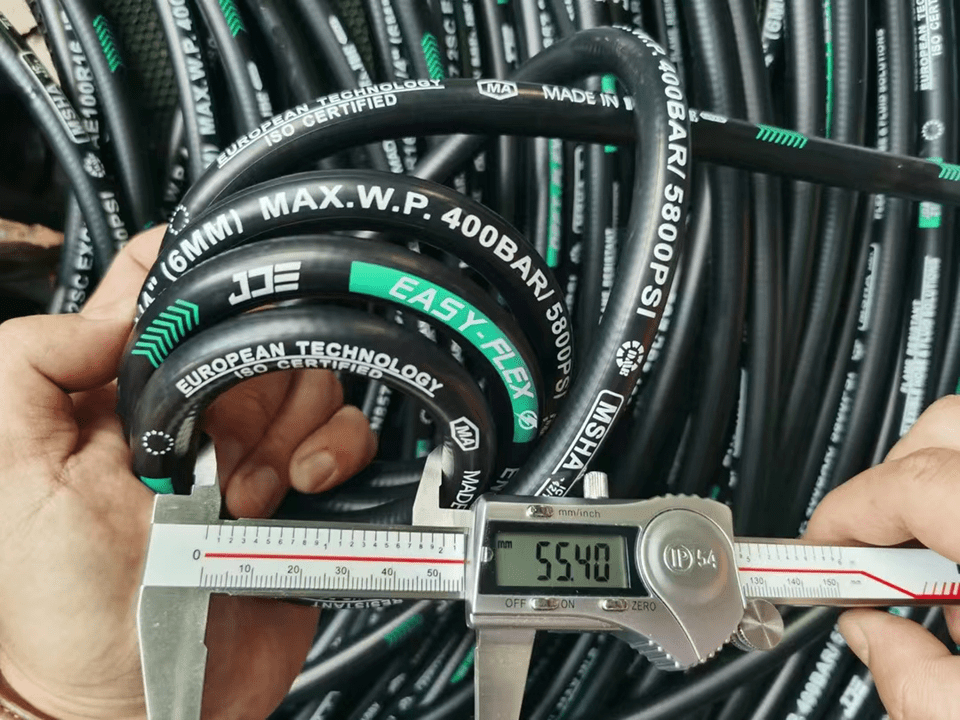

Product Bending Display Effect

The minimum bending radius of Easy-Flex Type Series hose is 55.4 mm, which is only half of the minimum bending radius of SAE standard, and can meet the use of smaller Spaces.

Easy-Flex Type Series Packaging Display

DME&JDE GROUP hose unique ID card 100% product traceability.

According to the bar code on the package, all the production information can be quickly confirmed, including the raw material climate information, production process and process production equipment operator information.

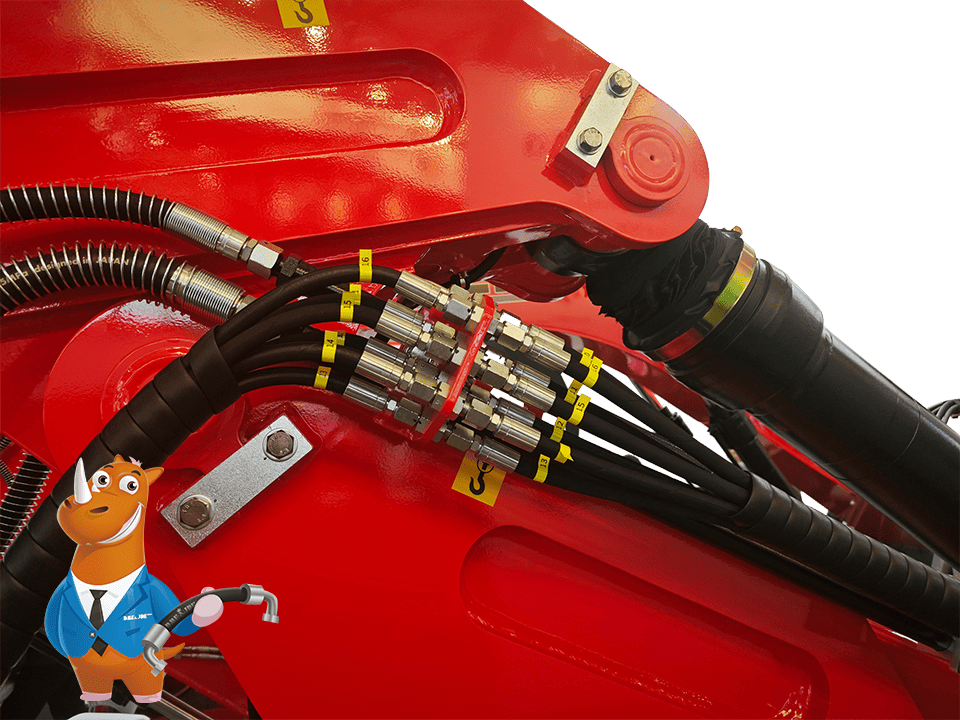

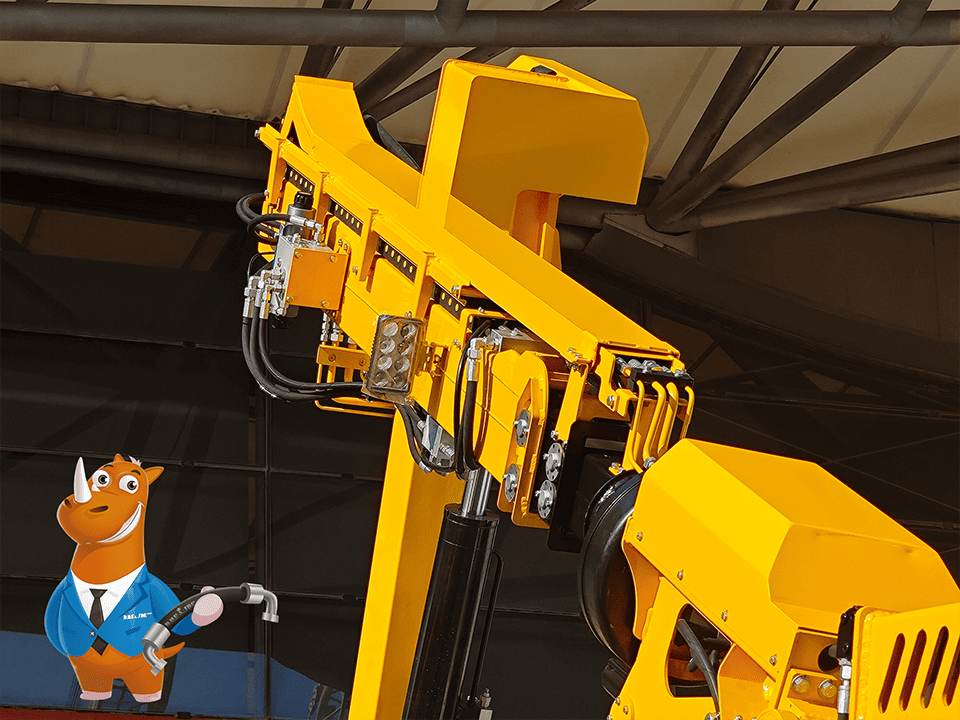

Application

FUTURE IS PROMISING

At DME&JDE GROUP, we believe that fit is the best. Therefore, compared with other manufacturers, DME&JDE GROUP can provide OEM solutions specific to your application.

![Several different types of DME&JDE flexible hoses are displayed.]()

![Several different types of DME&JDE fluid connector are displayed.]()

English

English 简体中文

简体中文