Dec. 17, 2021

Advantages & Disadvantages Of DEM Hose Nipple And Fitting Sealing Type

Niuniu introduced the components of DME hose fitting. In this issue, Niuniu will introduce the advantages and disadvantages of DME hose nipple and fitting sealing type in detail.

The sealing mode of hose nipple and fitting is an important factor to be considered in the selection of hydraulic hose fitting, which plays a vital role in the normal operation of the whole hydraulic system.

Let's review the sealing type of DME nipple:

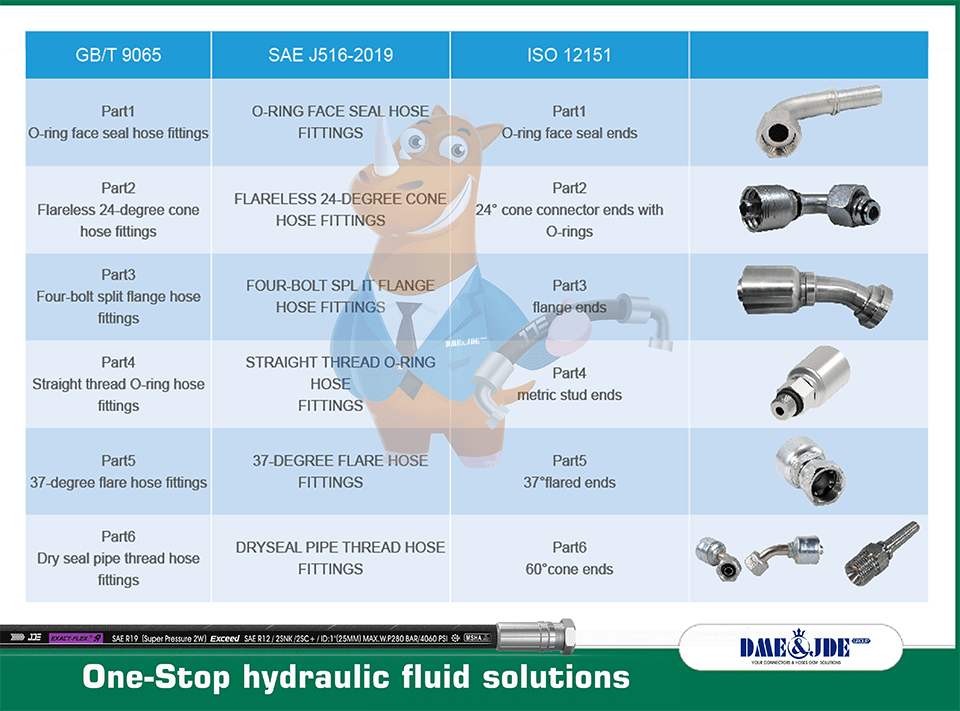

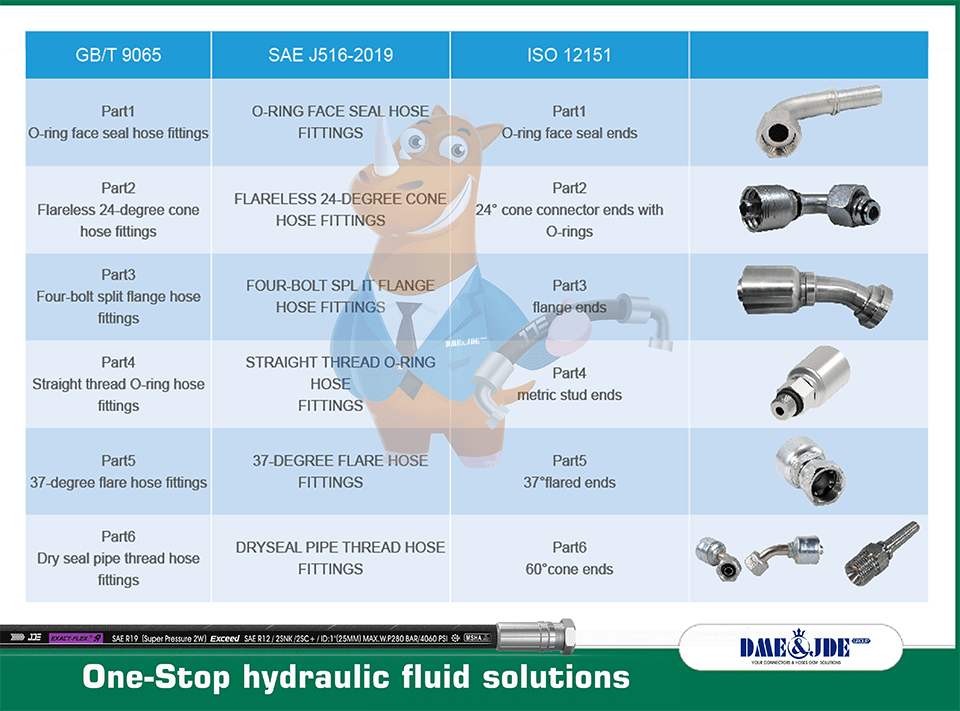

According to the comparison of hose fittings standards GB/T 9065, SAE J516-2019 and ISO 12151, we found that GB/T 9065 and ISO 12151 classification and description are basically the same, the above two standards and SAE J516-2019 comparison, only Part 6 of SAE J516-2019 differs from the above two standards, one is a 60°cone ends and the other is dry seal pipe thread hose fittings.

Next, Niuniu will introduce the advantages and disadvantages of the above six nipple sealing types of DME in detail:

-

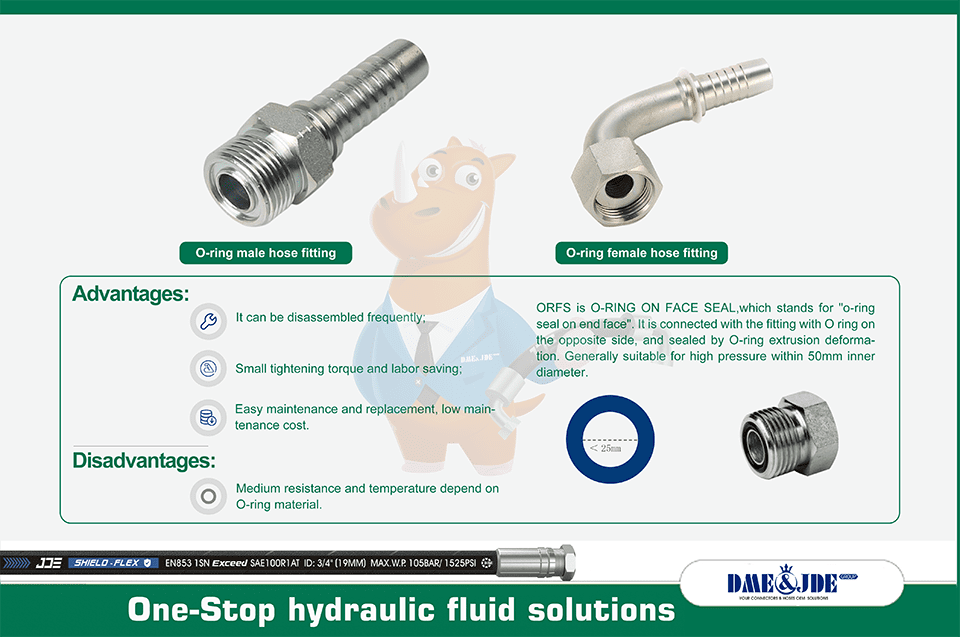

O-ring face seal hose fittings

-

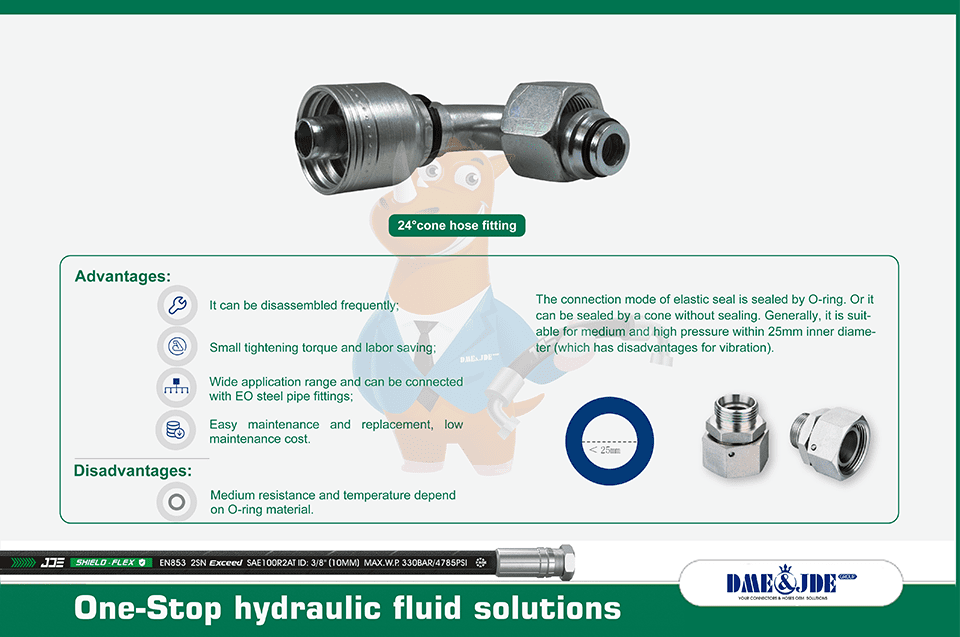

24° cone sealed end hose fitting

-

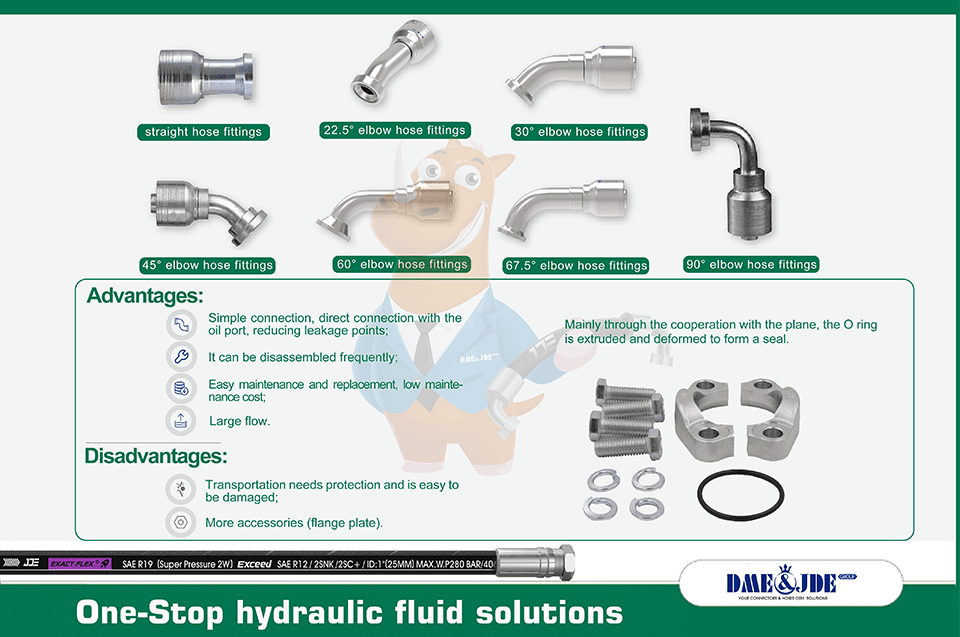

Flange hose fittings

-

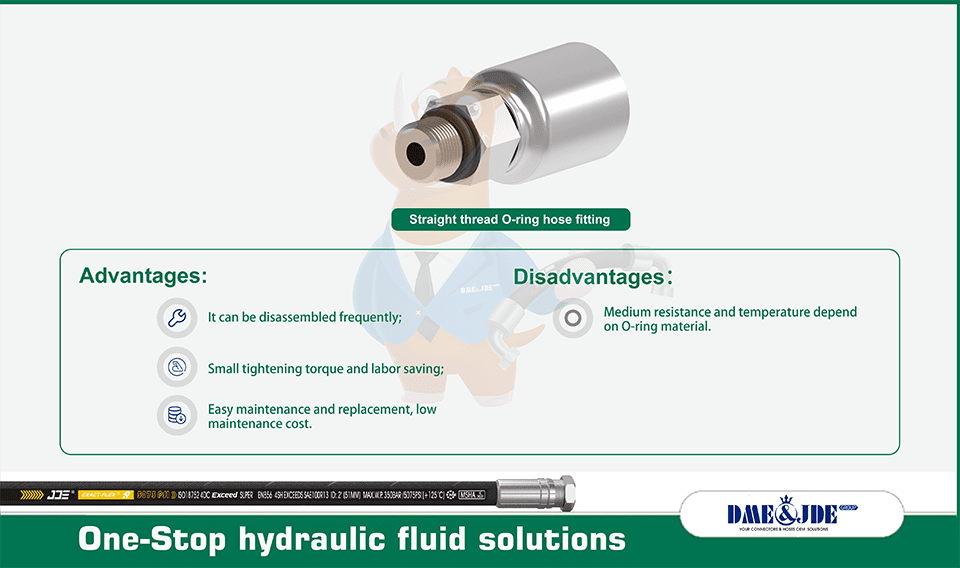

Straight thread O-ring hose fitting

-

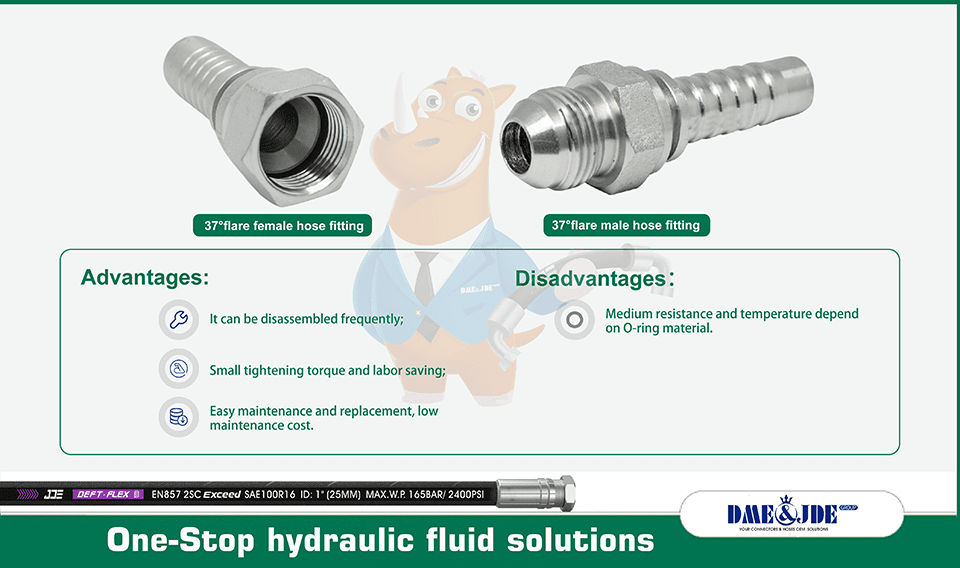

37° flare hose fitting

-

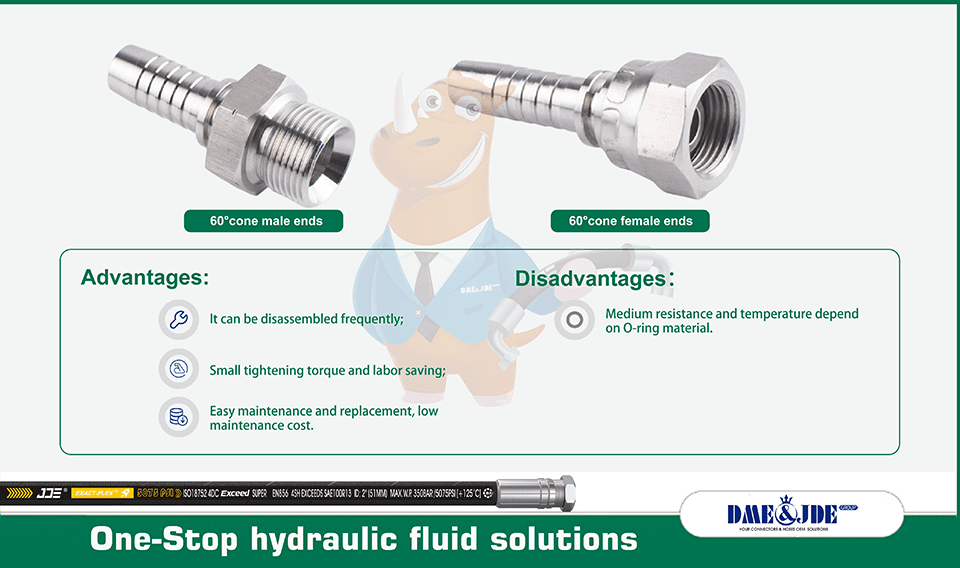

60° cone ends

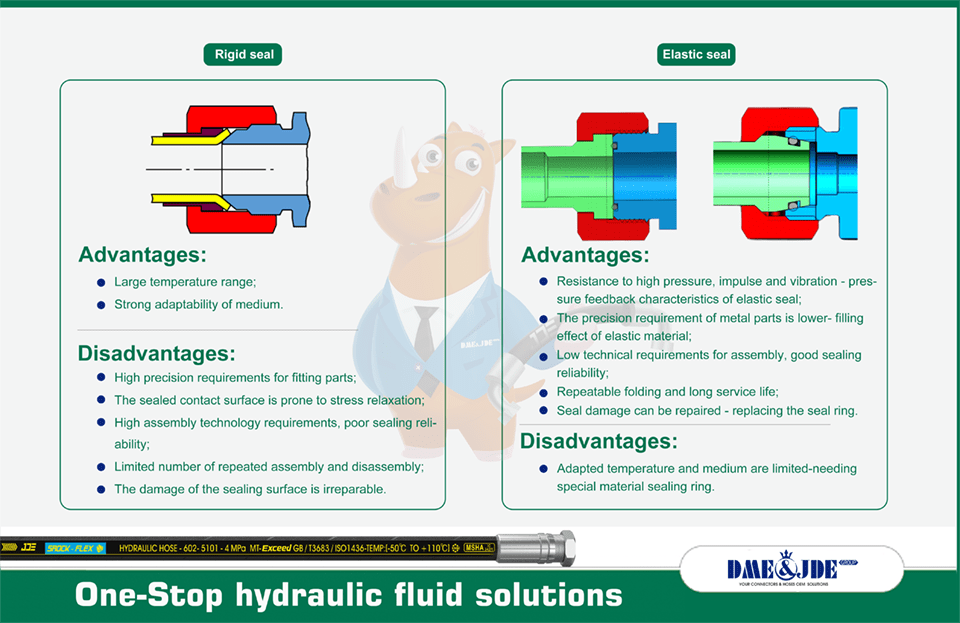

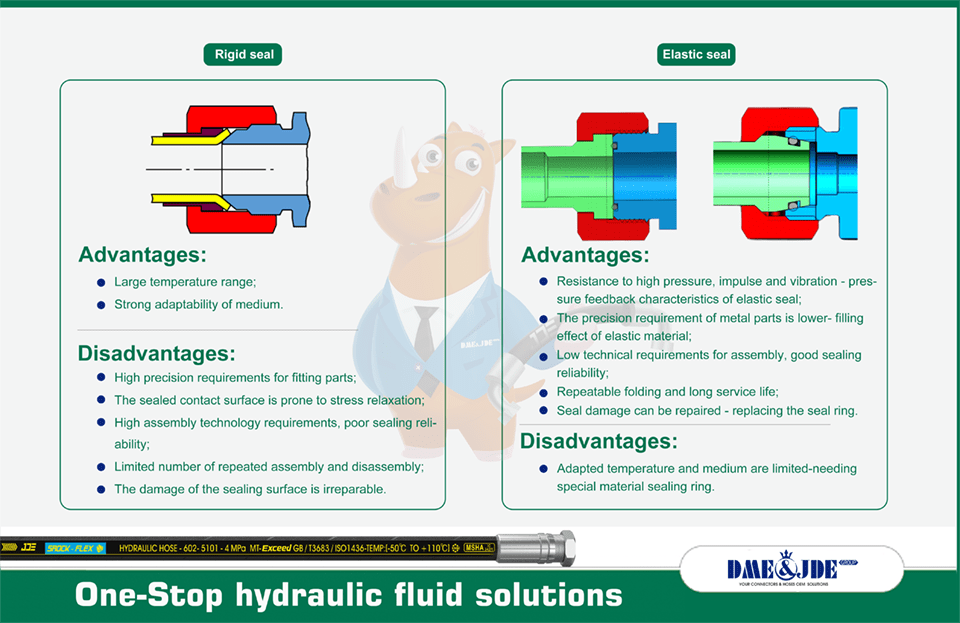

Thirdly, Niuniu will introduce the sealing types of DME fitting, which can be divided into rigid seal and elastic seal. The advantages and disadvantages are as follows:

Whether rigid seal or elastic seal, the thread provides mechanical support and sealing support, is an important part of the fitting and an important criterion for the classification of the fitting.

Finally, Niuniu will share some fitting knowledge, hoping to be helpful to you.

-

Distinguish weight fittings

According to the different pressure grades, the fittings of the same specification also have weight points. The light series is suitable for 3000 psi class and the heavy series for 6000 psi class.

-

Distinguish 24° cone weight series

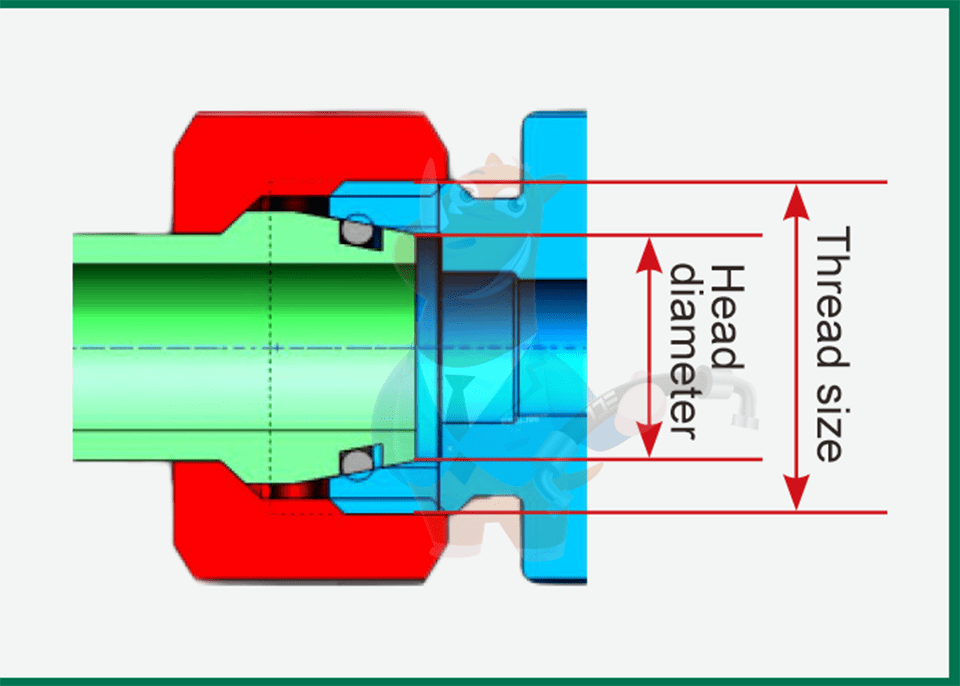

Head outer diameter D < 14 mm, can be determined by measuring thread size.

Head outer diameter D > 14 mm, can be directly determined.

Nipple tail weight can be determined according to the hose.

-

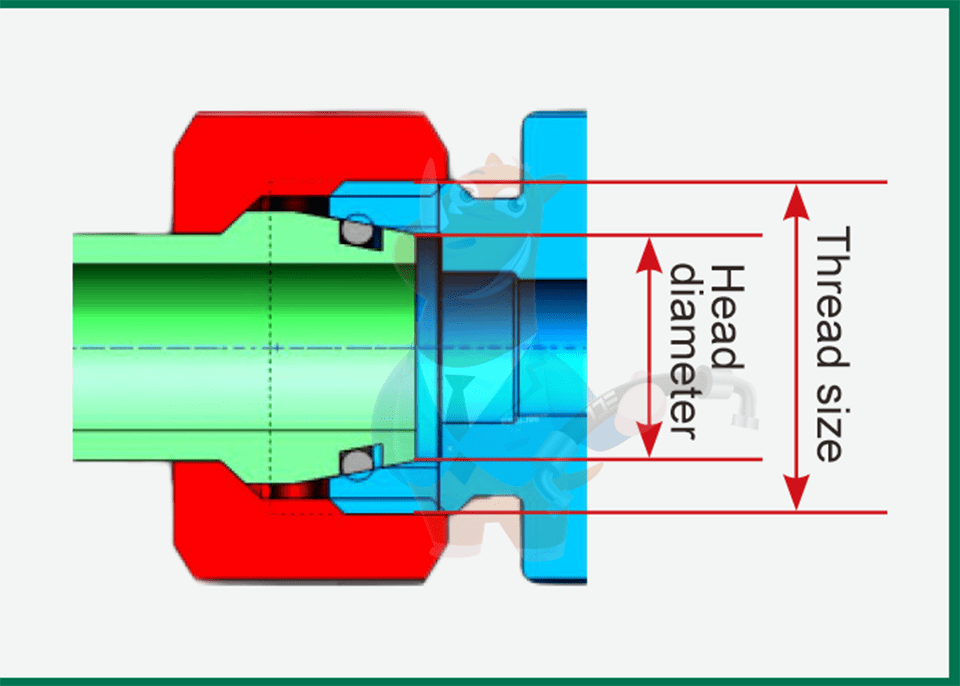

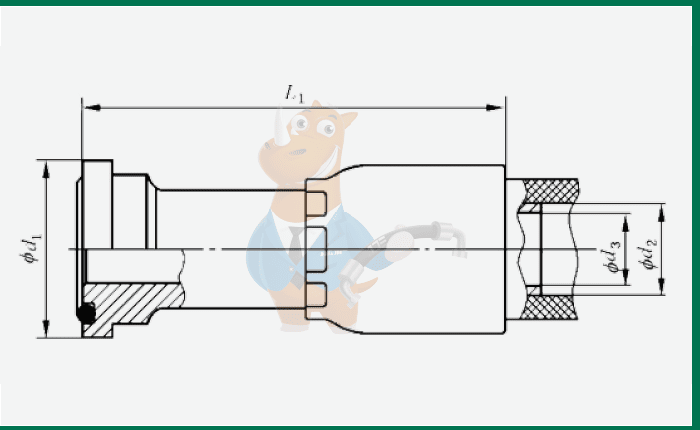

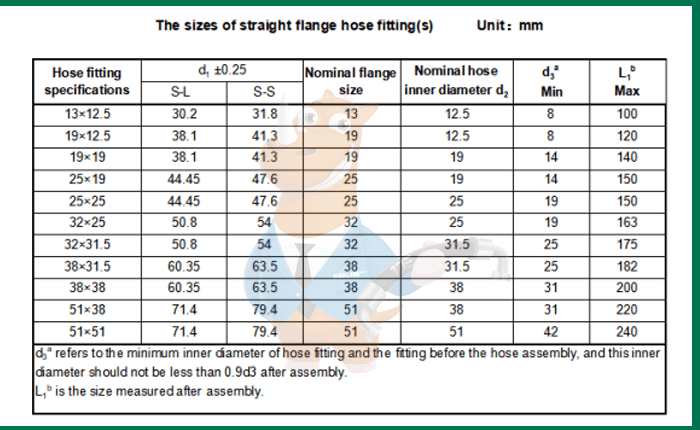

Distinguish SAE flange weight series

Take the straight flange hose fitting(s) as an example, the hose joint specification is determined, and different d1 sizes can distinguish the weight series of flanges. The reference standard GB/T 9065.3-2020.

-

JIC Association and SAE Association

- JIC: Joint Industry Conference, U.S.A., American Joint Industry Association/American Joint Industry Committee;

This committee selected some of their favorite specifications from UN threads for their own use, and the specifications they selected were called JIC standard.

- SAE: Society of Automotive Engineers is American society of automotive engineers; The association also picked out some of them, called SAE standard.

Through the introduction of these issues, I believe you have a detailed understanding of DME hose fitting. DME&JDE Group's comprehensive and diversified product series can provide customers with one-stop hydraulic fluid solutions to reduce the demand for multiple suppliers, thus reducing customers' related costs. Selecting the correct DME&JDE brand hydraulic hose and fitting will prolong its service life.

![Several different types of DME&JDE flexible hoses are displayed.]()

![Several different types of DME&JDE fluid connector are displayed.]()

English

English 简体中文

简体中文