Oct 22, 2021

Classification & Marking Method of DME Hydraulic Hose Fittings

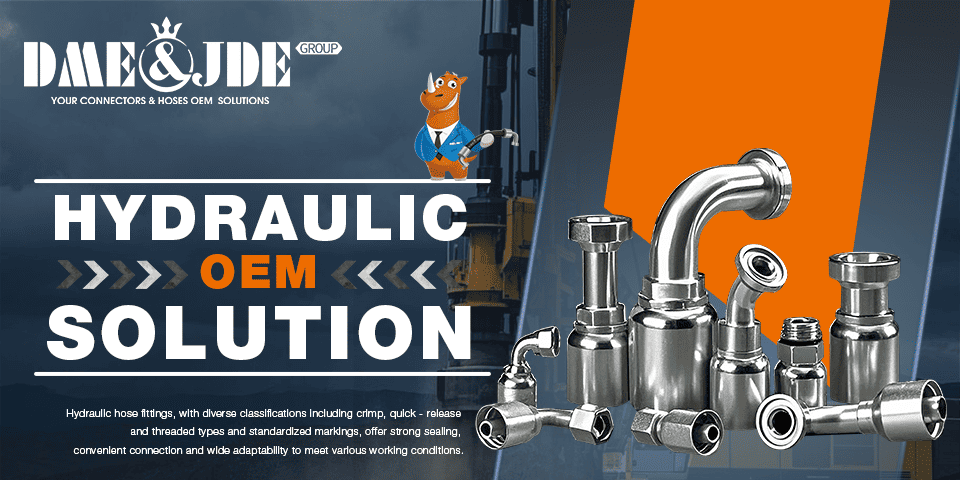

In the industrial fluid transmission system, DME hose connectors play a crucial role. Having a clear understanding of the types of these fittings and the standardized marking methods is essential for ensuring the efficient operation and the safety and stability of the system.

The Cruciality of Hydraulic Connectors

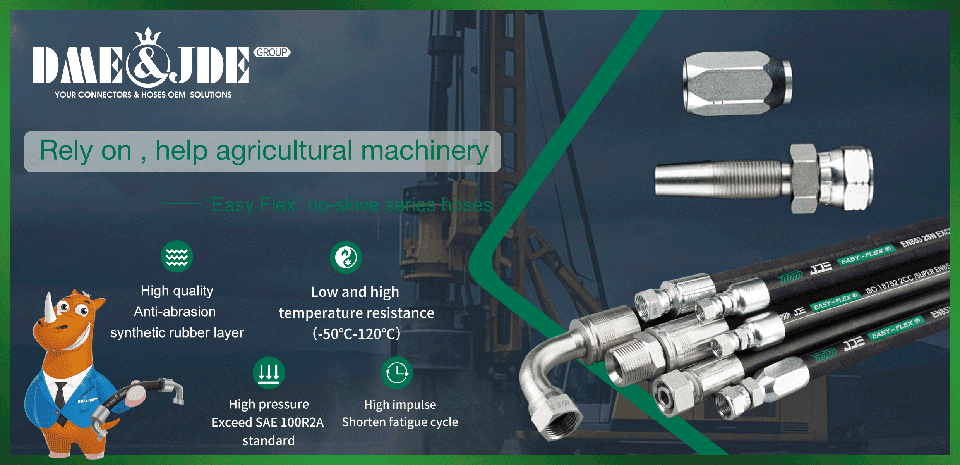

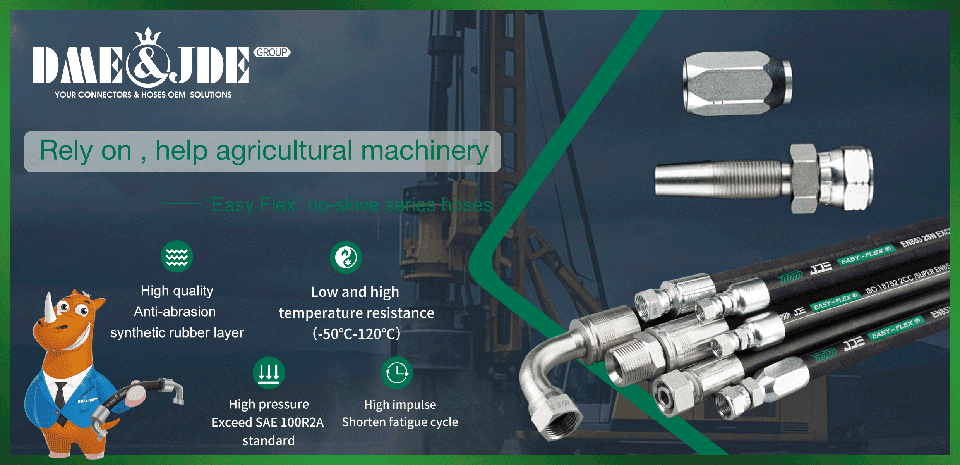

Hydraulic hose assemblies are widely used in numerous fields. Regardless of the harsh working environments they are in, they shoulder the important task of conveying fluids under extreme pressure and providing power for equipment operation. To ensure the safe and efficient operation of the system, hydraulic hose assemblies must be equipped with hoses that can meet the application pressure requirements and flow rates, as well as suitable hose fittings. At the same time, the installation of the fittings onto the hoses must be precise.

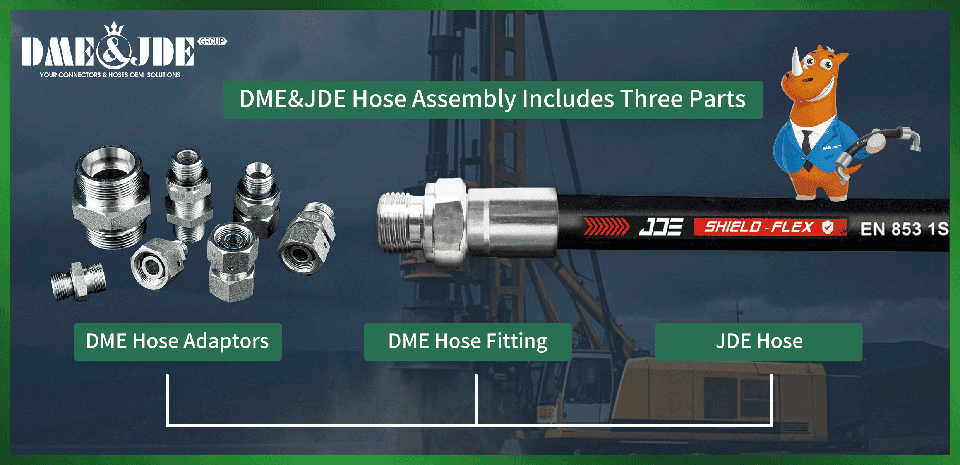

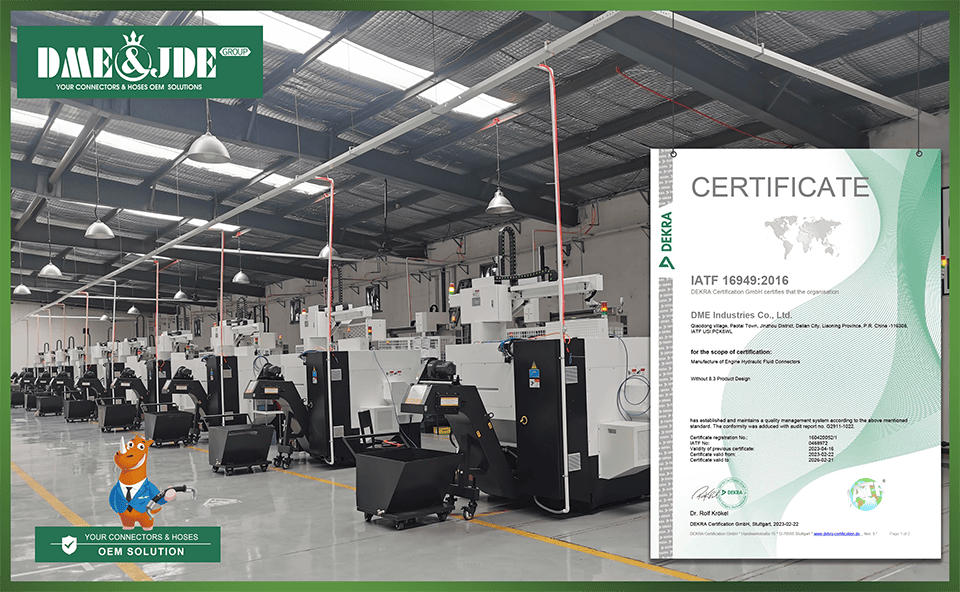

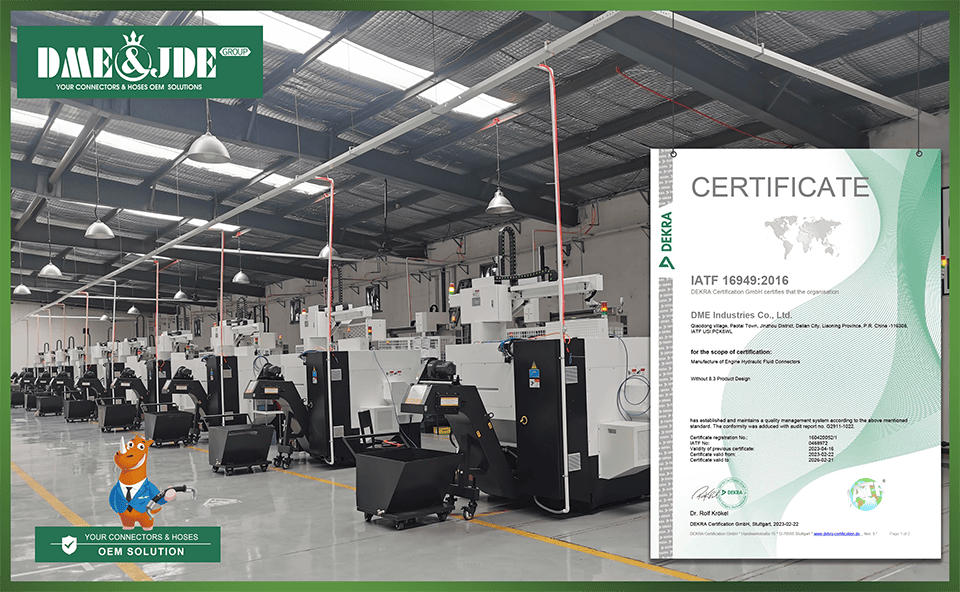

The DME&JDE Group has always attached great importance to research and development investment and technological innovation. Relying on its profound technical accumulation and continuous exploration, the hose assemblies produced by the group not only comprehensively exceed industry standards but also frequently surpass customers' expectations with their excellent quality and performance. We actively expand our global cooperation network and collaborate with professional partners around the world, aiming to quickly customize OEM fluid solutions for hydraulic hoses and fittings for customers, and assist customers in various industries in achieving efficient and reliable fluid transmission under complex working conditions.

As a crucial connecting component in the hydraulic system, the hose fitting shoulders the important task of orderly connecting various hydraulic components, enabling these components to jointly form a closed-loop hydraulic system and ensuring the stable operation and smooth power transmission of the entire system.

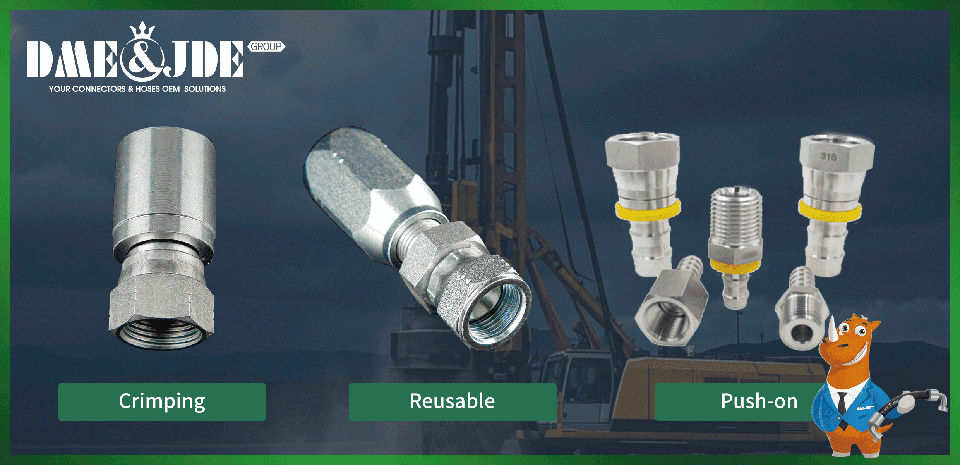

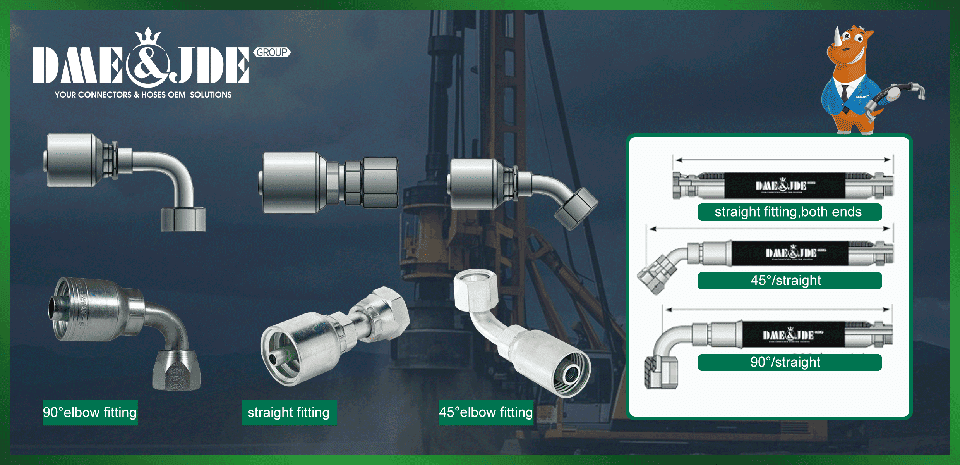

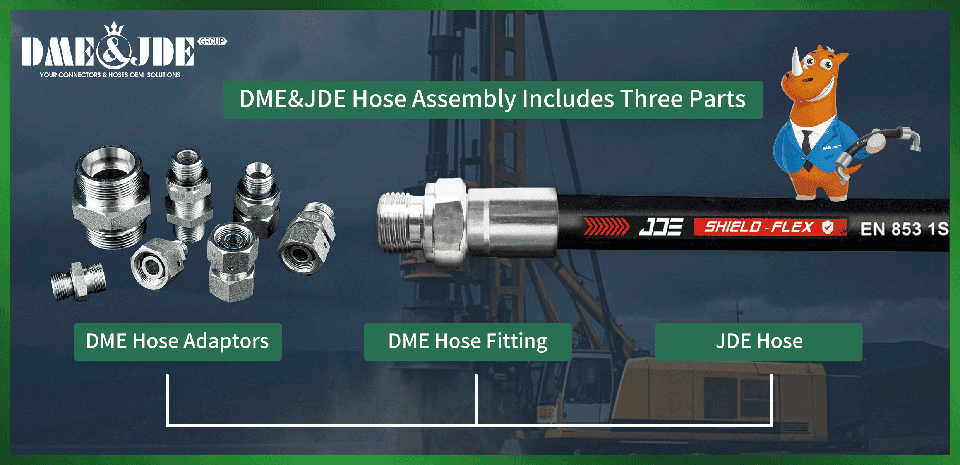

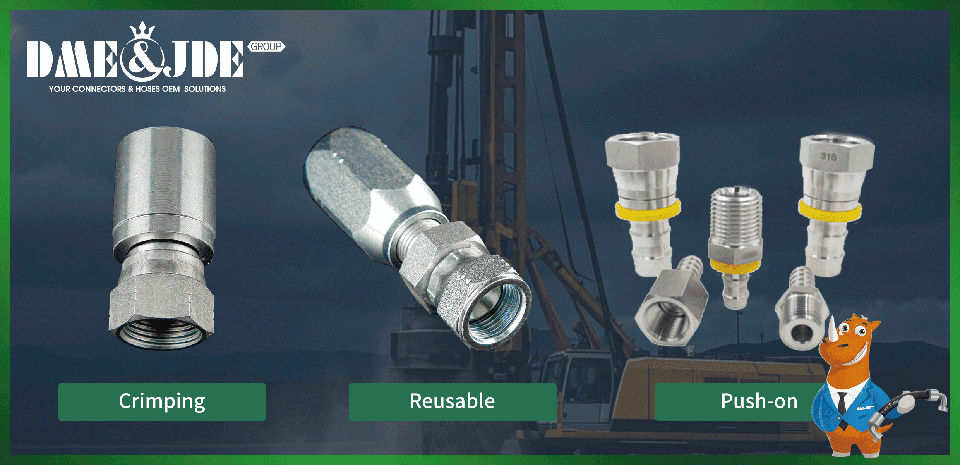

Hose fittings come in a variety of types, mainly including Crimp-type Hose Fittings, Detachable Hose Fittings, Snap-lock Hose Fittings, etc. Among them, crimp-type hose fittings are the most widely used in hose assemblies. Next, taking our DME&JDE brand fittings and hoses as examples, we will introduce the relevant details of crimp-type hose fittings to you with emphasis.

DME Crimping Hose Fittings

1.1 DME Crimping Hose Fittings

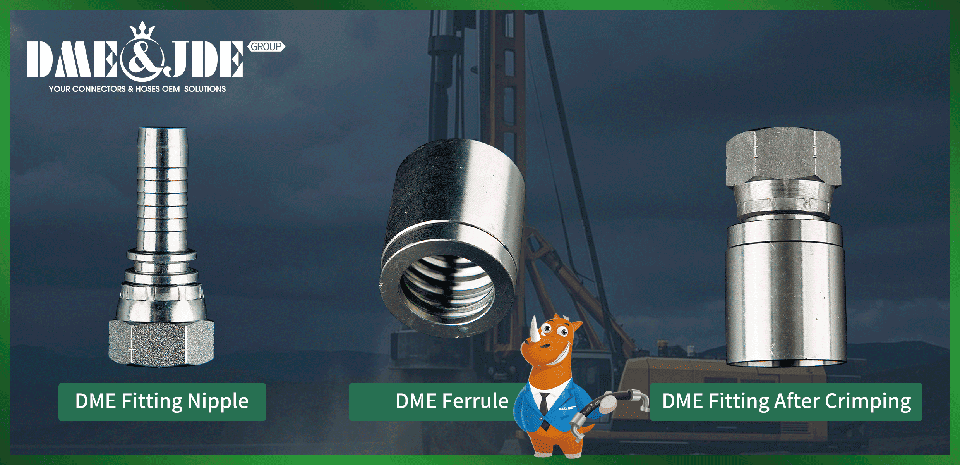

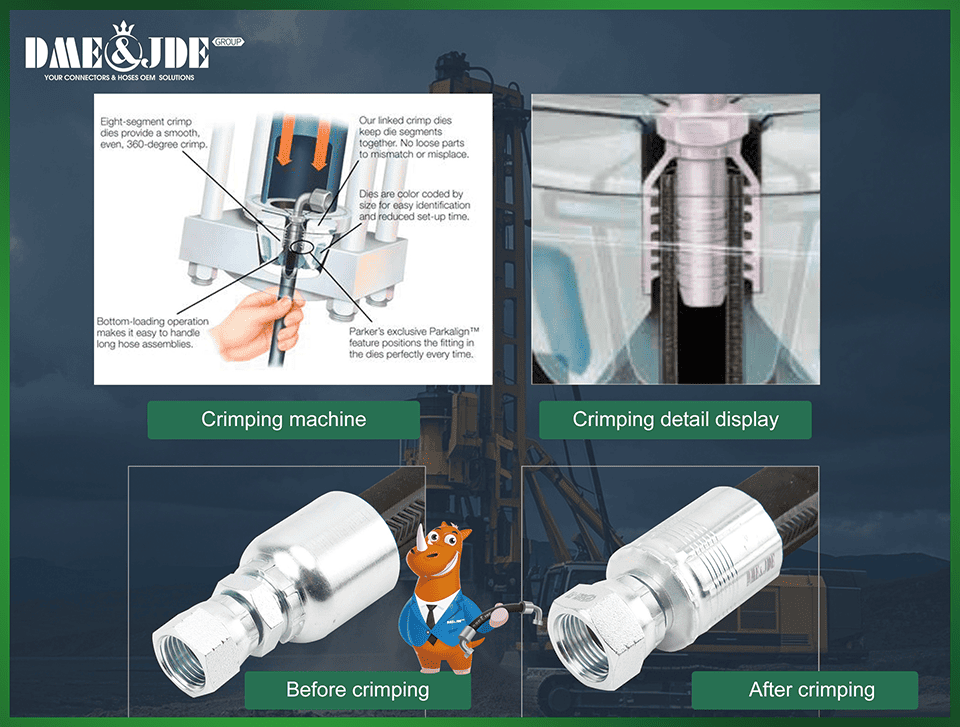

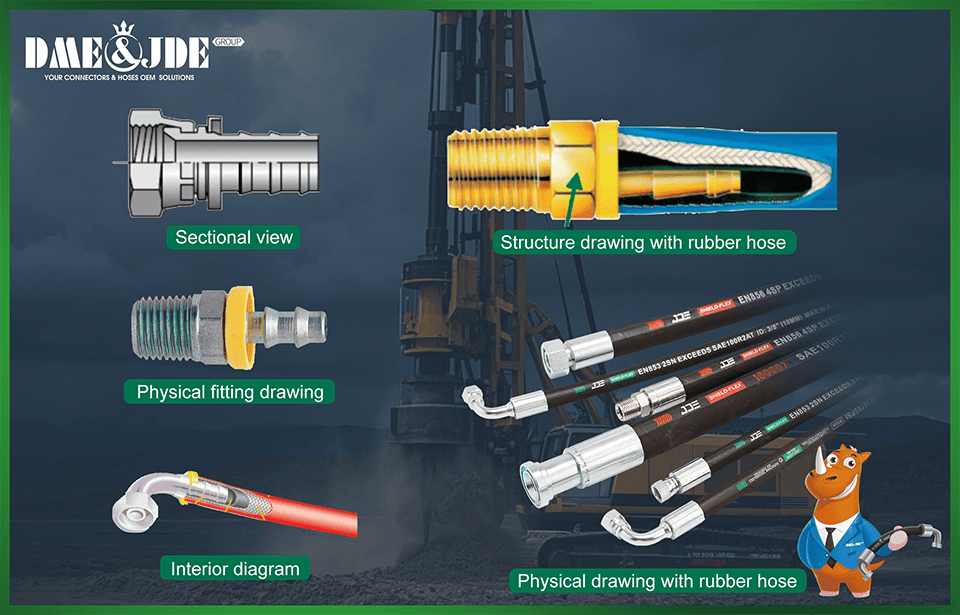

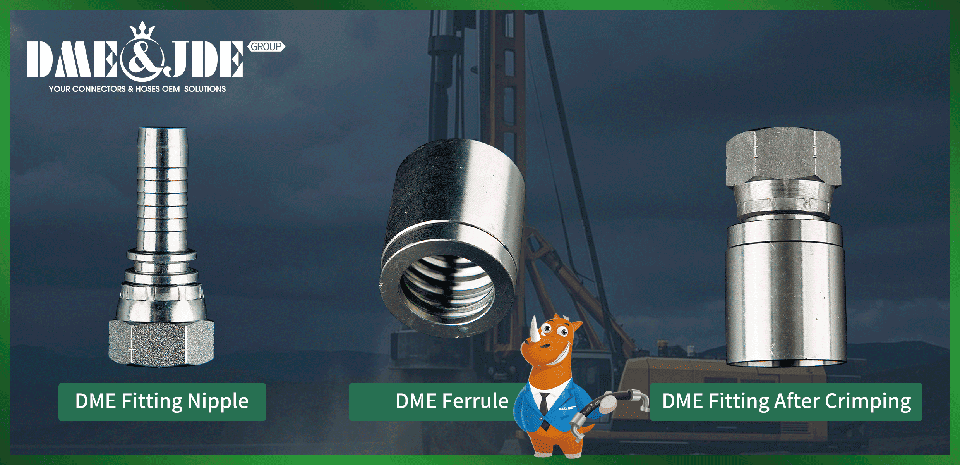

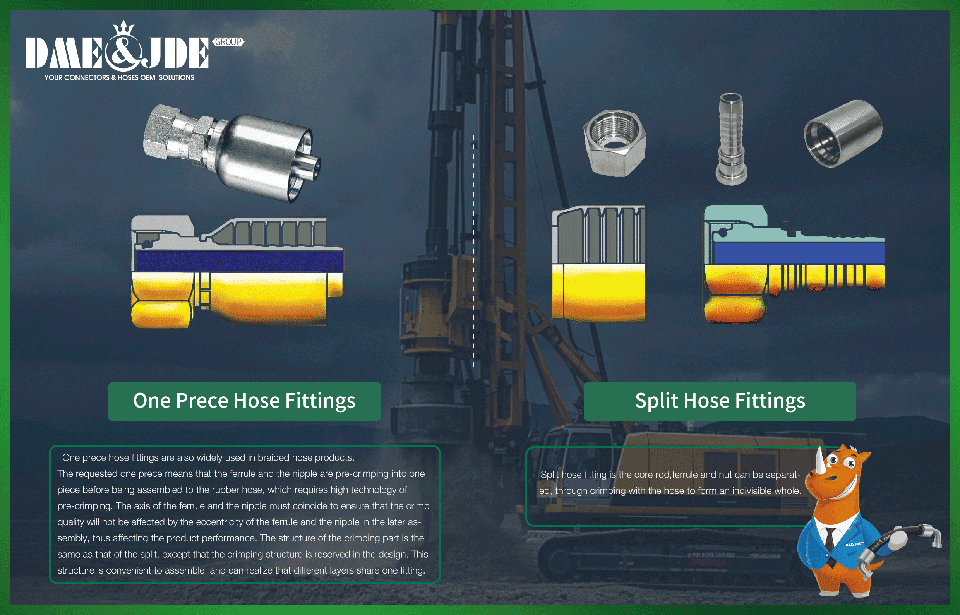

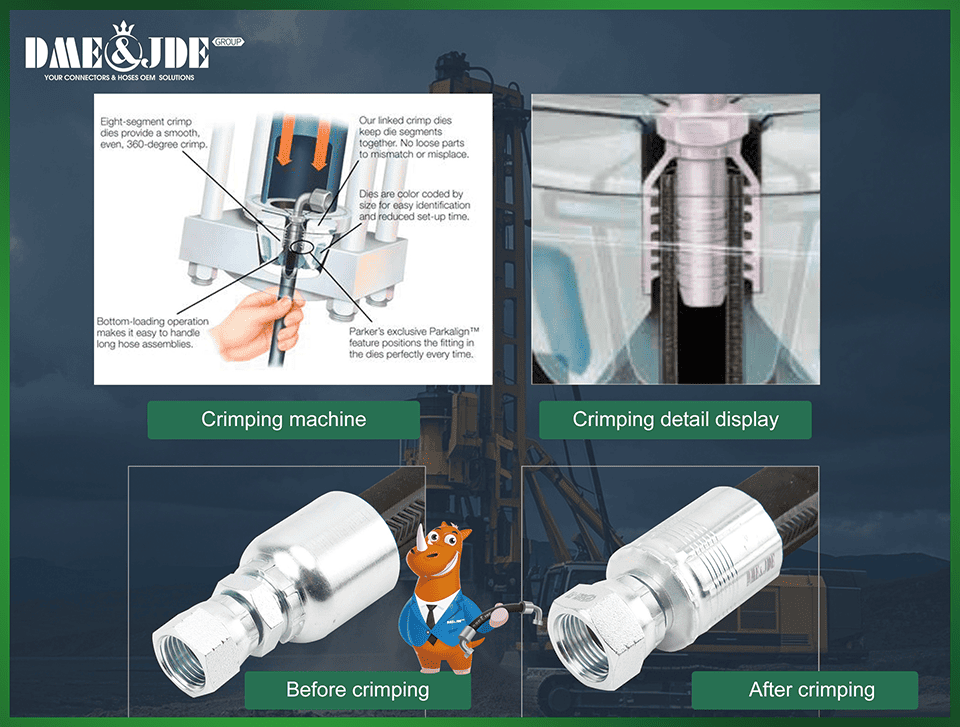

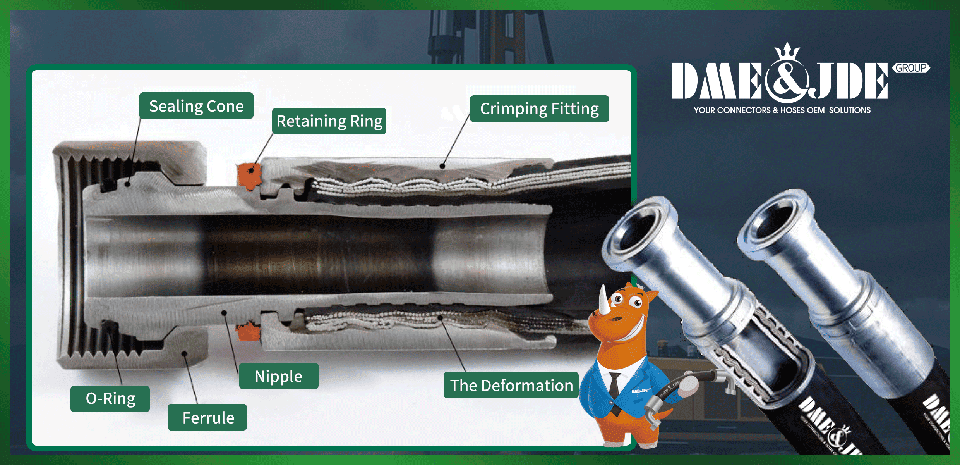

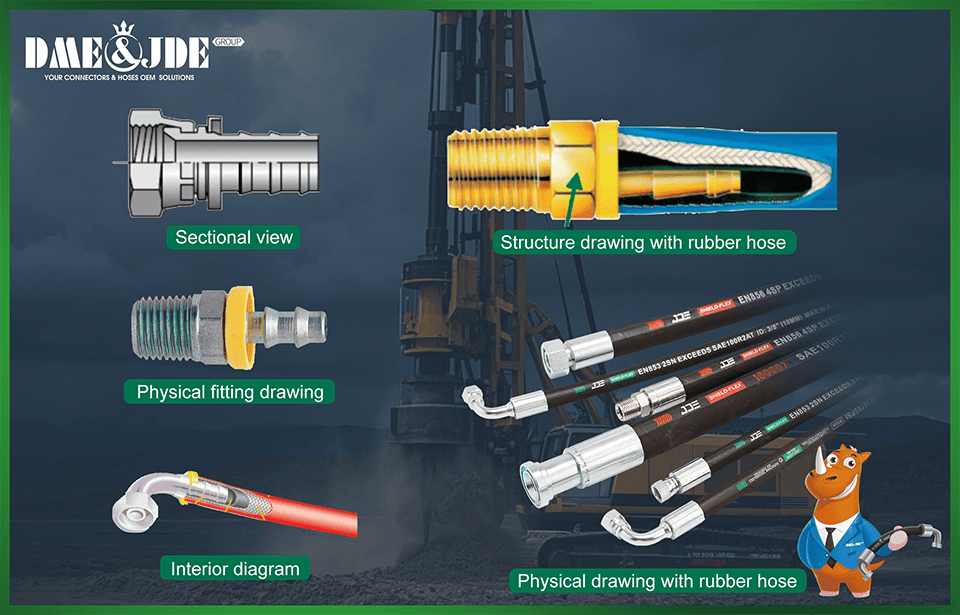

The DME crimp-type fitting is mainly composed of parts such as the fitting core, the outer sleeve (the nut is an optional part). During assembly, first assemble the fitting core, the hose and the outer sleeve. Then, under the uniform extrusion of the eight-petal crimping module of the crimping machine, the fitting and the hose will undergo a certain degree of plastic deformation, thus closely combining into a whole. In order to give full play to the performance of this type of DME fitting, we recommend using our "Super Shield" series hoses such as EN856 4SP/4SH in combination. The two have an excellent matching degree, which can significantly improve the reliability and stability of the hydraulic system.

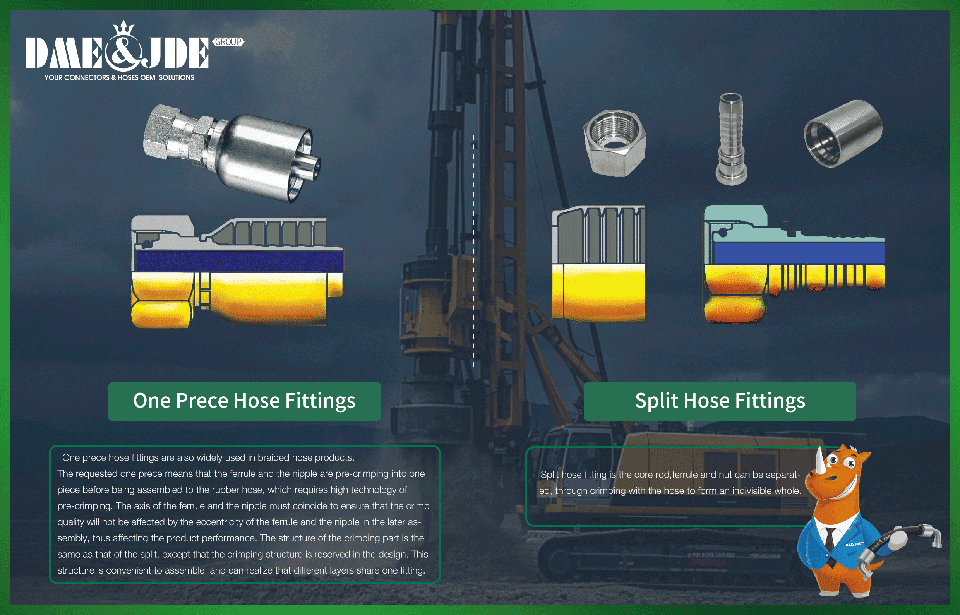

The crimping hose fitting is divided into two kinds: one piece and split.

1.2 The Crimping Process of JDE Hoses and DME Hose Fittings

In the production process, the outer rubber at the crimping positions such as the end of the JDE hose should be stripped first to expose the steel wire layer, ensuring that the steel wires are not damaged. Subsequently, measure the outer diameter and inner diameter of the steel wire layer of the hose, group them accordingly, and calculate the crimping parameters accurately. During the assembly, first insert the hose into the outer sleeve, then insert the fitting core into the hose. Finally, carry out the crimping operation on the crimping surface of the hose fitting according to the crimping parameters corresponding to the hose groups.

1.3 JDE hose crimping form and characteristics

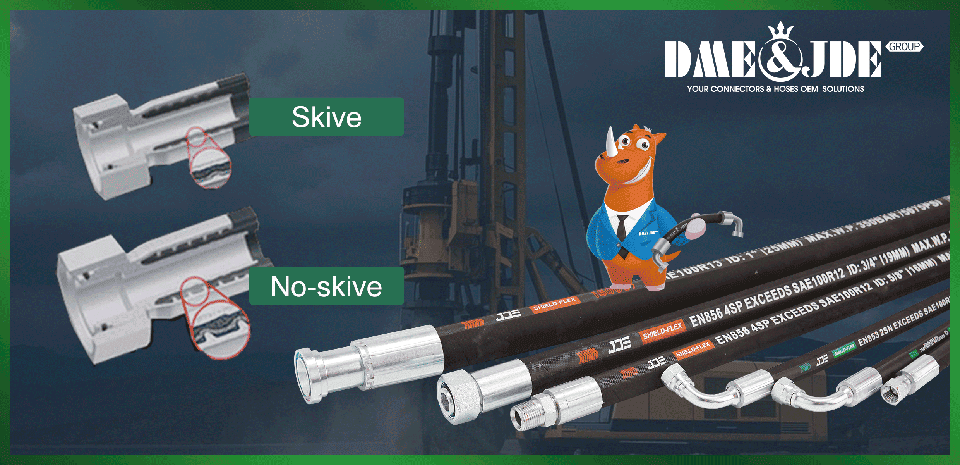

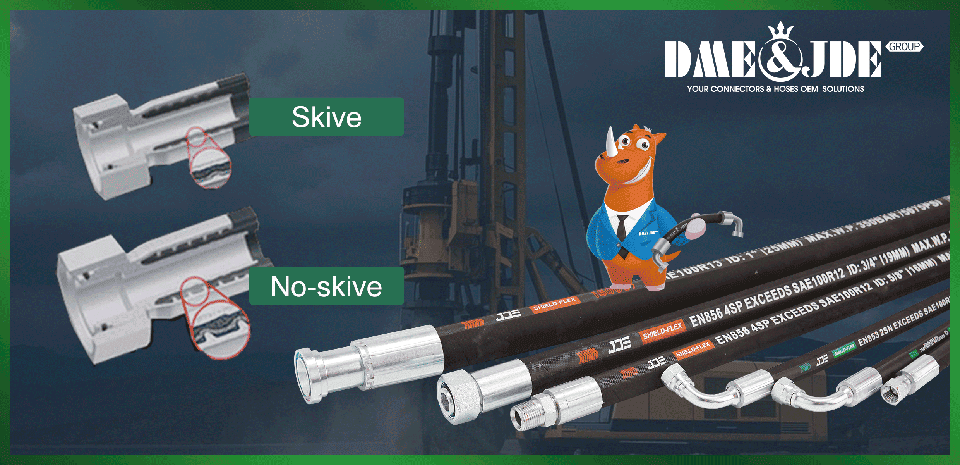

The selection of the crimping form of the hose mainly depends on the type of the hose, the dimensions of the inner rubber layer and the outer rubber layer, as well as the actual applied pressure-bearing environment of the hose assembly. There are mainly three types of crimping forms: crimping without skiving, crimping with the outer rubber layer skived off, and crimping with both the inner and outer rubber layers skived off.

Characteristics of Crimping Forms

-

Crimping without Skiving

During the operation, there is no need to strip the inner and outer rubber layers of the hose. Just complete the hose installation process, and then carry out the crimping operation to finish the product processing. This process has the advantage of simplicity and is often applicable to the wire braided hoses with a relatively thin outer rubber layer that comply with standards such as GB/T3683, EN853, and SAE.

-

Crimping with the Outer Rubber Layer Skived Off

For hoses with a thick outer rubber layer, a certain length of the outer rubber layer needs to be stripped in advance. This measure aims to enable the steel wire reinforcement layer to make more sufficient contact with the tooth grooves of the outer sleeve. When the outer sleeve undergoes shrinkage plastic deformation under the action of external force, it can firmly hold the steel wires, effectively preventing the joint from being pulled off under high-pressure impact. This crimping form is mainly applicable to the steel wire spiral-wound hoses that comply with standards such as GB/T10544, EN856, and SAE.

-

Crimping with Both the Inner and Outer Rubber Layers Skived Off

For hoses with thick inner and outer rubber layers, a certain length of both the inner and outer rubber layers needs to be stripped. During the crimping process, the steel wire layer and the inner rubber layer will be extruded into a wavy shape. This form is generally applicable to large-sized (nominal size 32 and above) ultra-high-pressure steel wire spiral-wound hoses that comply with standards such as GB/T10544, EN856 - R13, and R15.

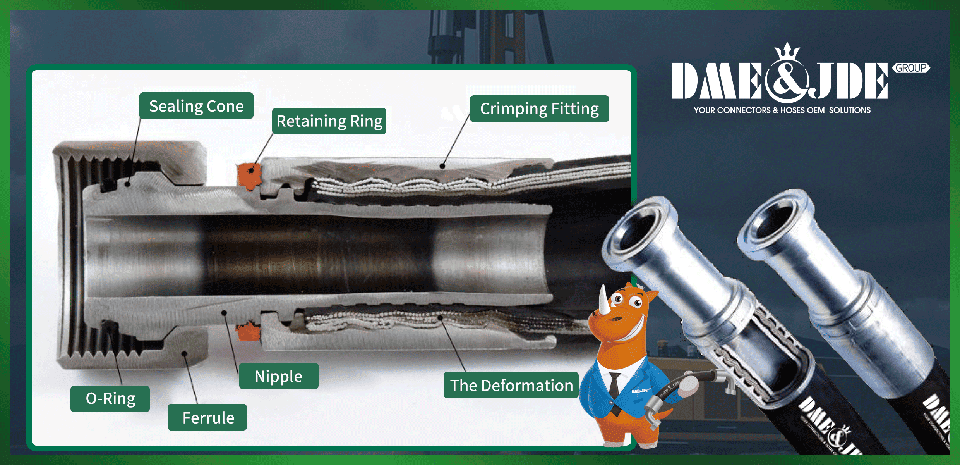

1.4 The structure of the DME fitting after crimping

The ideal crimping state should be that the teeth of the sleeve firmly grip the steel wire reinforcement layer. At the gripping position, the teeth undergo an appropriate amount of deformation to ensure a tight interlock between them. At the same time, the core fits snugly with the inner rubber, forming an effective sealing structure on the contact surface and achieving excellent sealing performance.

1.5 DME Snap-lock Type Fitting

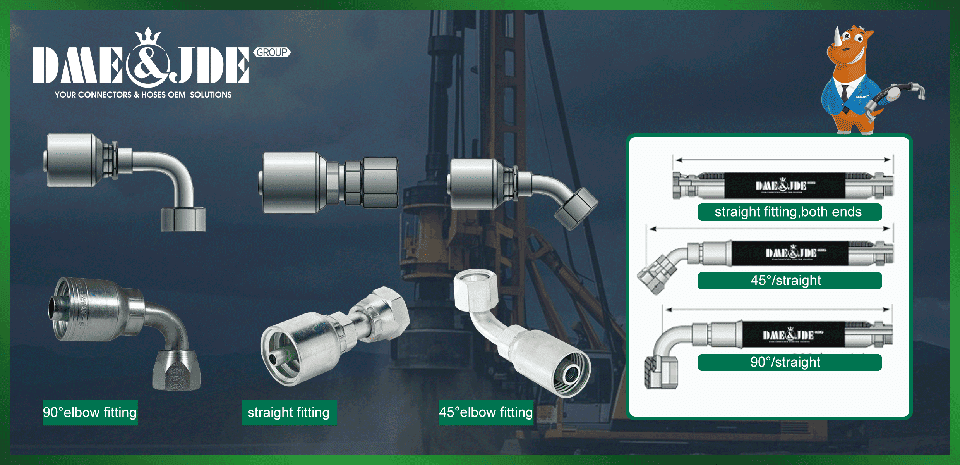

In addition to the above-mentioned elbows, we offer a variety of bend angles, including 22.5°, 30°, 60°, and other specifications. You can flexibly choose the appropriate joint style and bend angle according to your actual needs. Having introduced the DME crimp-type hose fittings, we will now briefly introduce several other types of hose fittings from DME DiMei.

DME reusable fittings

The DME detachable hose fitting connects by compressing the hose with a fitting core that has an external cone, causing the hose to closely adhere to the internal cone of the fitting sleeve, forming a connection with a large bonding force. We recommend using our "Yirui" series hoses, such as those of ISO18752 1BS/2BS specifications, to match this type of DME fitting.

DME push-on fittings

The DME snap-lock type hose fitting is a kind of hose fitting that allows for the quick and easy fabrication of hose assemblies on-site without the need for special tools. It is suitable for low-pressure hoses. We recommend using our "Super Shield" series hoses, such as SAE R6 and SAE R3, to match this type of DME fitting.

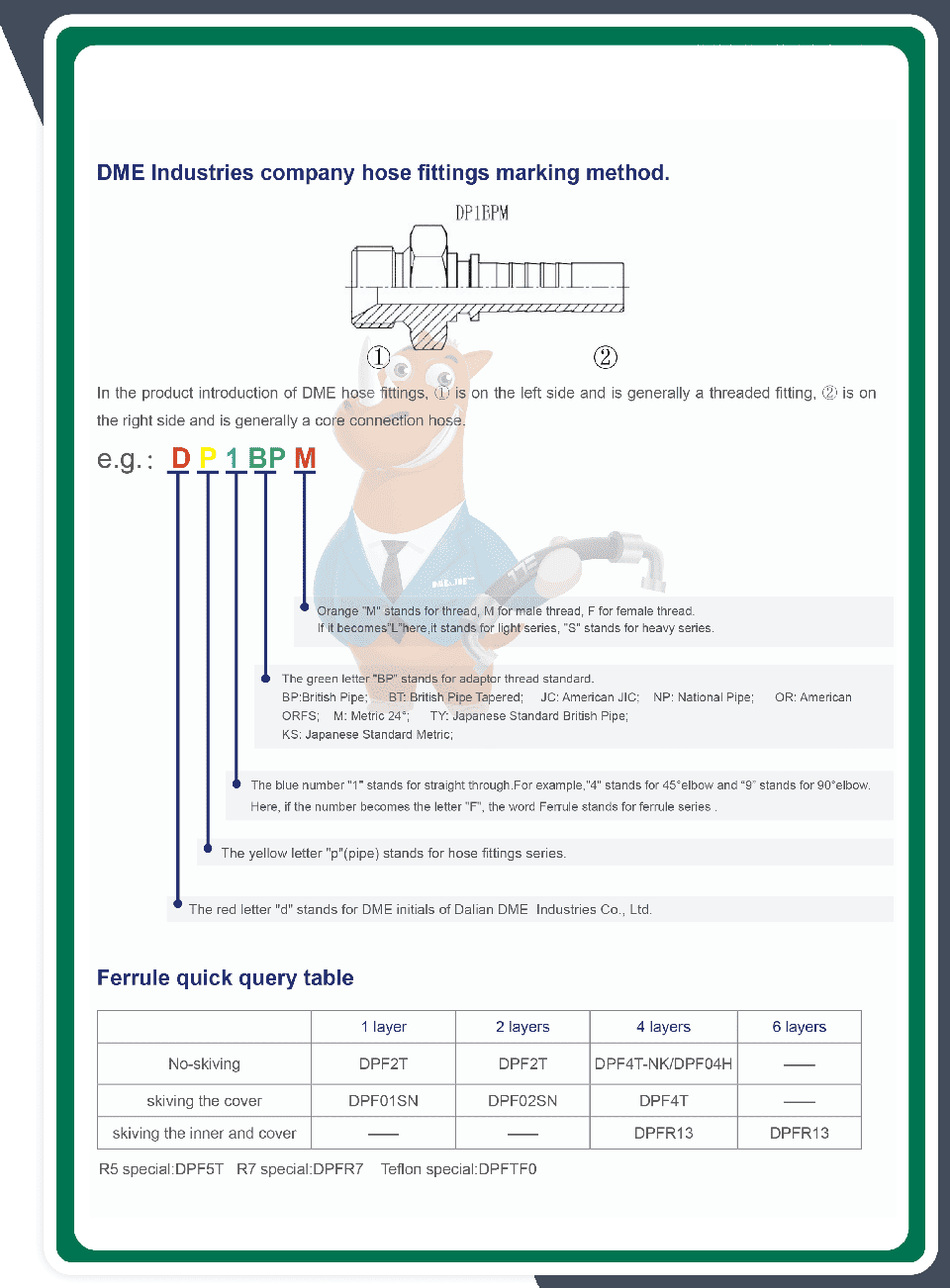

Marking method of DME fittings

I believe the introduction of DME hose fittings will help you understand this product comprehensively and deeply.

Please feel confident in choosing the high-quality hydraulic hoses and fittings crafted with ingenuity by DME&JDE. With their outstanding performance and quality, they can not only effectively enhance the operational efficiency of the system and significantly reduce downtime but also help your industrial hydraulic system unleash its maximum production capacity and stand out in the fierce market competition.

![Several different types of DME&JDE flexible hoses are displayed.]()

![Several different types of DME&JDE fluid connector are displayed.]()

English

English 简体中文

简体中文